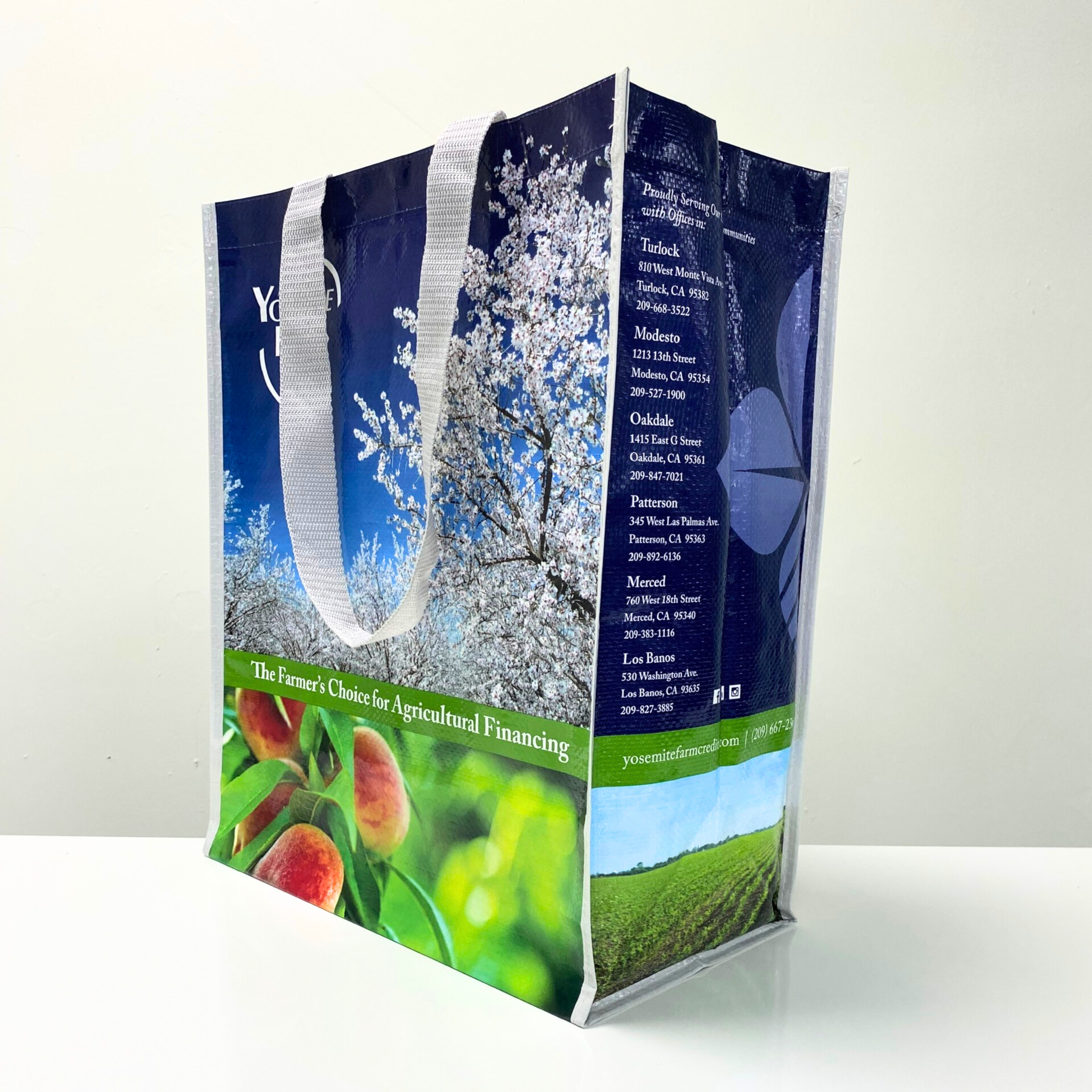

K-Packings: #1 Vietnam Wholesale Reusable Bags, Bulk Gift Packaging

BEST PRICE, BEST QUALITY

Are you looking for packaging solutions at reasonable prices and top quality? Then congratulations, you have come to the right place.

We have a manufacturing factory in Vietnam with strengths in production costs and labor. We can provide you with a variety of packaging at prices 5-10% cheaper than any other supplier, while still ensuring top quality. Another reason why you should choose K-Packings is because we strictly comply with environmental protection principles…