FIBC Bulk Bags are widely-used containers for storing large quantities of goods (often over 1 ton) and are utilized across various industries worldwide. The following article will provide comprehensive information on the types of bags, their characteristics, uses, and the manufacturing process of FIBC bags.

What is a FIBC Bag?

A Flexible Intermediate Bulk Container, also known as FIBC, is an industrial container made of flexible fabric designed for storing and transporting large quantities of various dry and bulk goods.

Due to its durable nature, reusability, and versatility for different types of goods, FIBC bags have become an ideal storage solution, replacing traditional options like wooden pallets, plastic drums, or metal containers. These bags can withstand loads ranging from 500kgs-2000kgs.

Other Terms for FIBC Bags

Depending on the industry, type of goods stored, application, or the carrying capacity of the bag, FIBC bags are also known by various other names, such as:

- Jumbo Bags

- Bulk Bags

- Super Sacks

- Bulk Sacks

- Big Bags

- Super Bags

- One-ton Bags

What Are FIBC Bags Made Of?

FIBC bags are manufactured from various materials, but the most common material is polypropylene – a type of flexible plastic derived from petroleum. Polypropylene is known for its resistance to abrasion and degradation from chemical processes. Therefore, tightly woven polypropylene fibers are used to create highly durable FIBC bags, capable of holding heavy loads up to 2 tons. Particularly, this material is recyclable, making FIBC bags increasingly popular for use.

Benefits of Using FIBC Bulk Bags

In recent years, the use of FIBC bags has increased as a replacement for wooden or metal crates and boxes. Here are the top benefits of using FIBC bags:

- Improved Safety:

+ For workers: Manual handling of heavy and bulk materials can pose risks of injury. FIBC bags require the use of mechanical aids such as forklifts, pallet jacks, or hoists, reducing manual handling and improving safety and productivity for workers.

+ For products: Consumer goods and liquid products require safe transportation and hygienic storage. FIBC bags, made from durable, non-corrosive polypropylene fibers, protect stored goods, preventing moisture-related issues like mold and dangerous microbial growth.

- Cost Savings: Using large-capacity FIBC bags can save more money compared to using smaller bags. Additionally, their lightweight nature can help reduce transportation costs. Recycling FIBC bags also reduces the need for purchasing new materials, further saving costs.

- Space Efficiency: FIBC bags can be stacked, making transportation and handling easier. They can also be folded and compacted for efficient storage, freeing up floor space and racks.

- Reusability and Recycling: FIBC bags have a long lifecycle and can be reclaimed, recycled, and refurbished, saving costs for businesses, reducing waste, and being environmentally friendly.

- Improved Transport: FIBC bags are designed with lifting loops or sleeves, eliminating the need for additional lifting equipment. Their use eliminates the need for pallets or other loading aids, making stacking easier and freeing up space efficiently in trucks or on racks.

- Flexibility: FIBC bags are versatile and can be tailored to various sizes, shapes, and specifications to suit different products and applications, offering flexibility in storage and transportation solutions.

Uses of FIBC Bulk Bags

FIBC Bulk Bags are widely used across various industries for transporting and storing bulk materials. Here are some common uses:

- Chemical Industry: Manufacturers in the chemical industry utilize FIBC bags to transport hazardous substances such as chemicals, fertilizers, or plastics, protecting them from corrosion or degradation due to chemical reactions.

- Agriculture: Clean and waterproof FIBC bags are employed to transport large quantities of raw materials such as grains, flour, sugar, salt, and even liquids like syrup or edible oil.

- Construction and Building Materials: Industries related to construction materials, such as sand, gravel, cement, and aggregates, often use FIBCs for transportation due to their ability to withstand heavy loads of up to 2500kg.

- Mining and Minerals: The mining industry utilizes FIBCs to transport minerals and ores during the mining process.

- Pharmaceuticals: In the pharmaceutical industry, FIBCs are used to handle and transport bulk pharmaceutical ingredients (APIs), excipients, and other raw materials in large quantities, meeting strict safety and hygiene standards.

- Emergency Relief and Humanitarian Aid: During humanitarian crises or natural disasters, FIBCs are used to provide essential supplies such as food, water, and medical supplies to affected areas, or even to prevent soil erosion by blocking rocks and rivers.

What are the different types of FIBC bags?

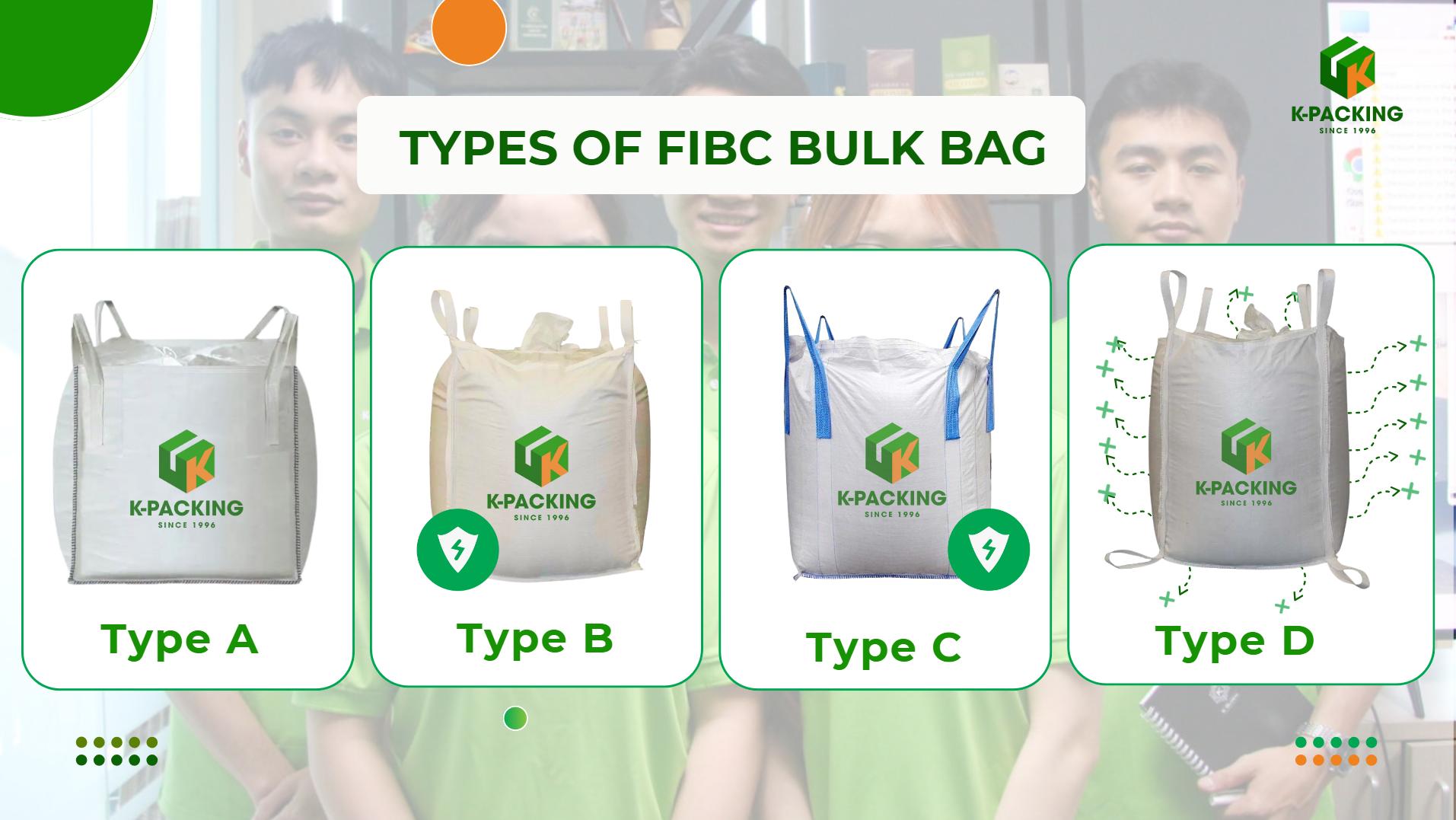

Type A FIBC Bags

Type A FIBC bags serve as standard industrial bags lacking electrostatic protection. They are crafted from conventional woven polypropylene and are outfitted with 4 reinforced lifting rings at each corner.

Type B FIBC Bags

Similar to Type A, Type B FIBC bags feature 4 reinforced lifting rings at each corner. They are another variant manufactured using conventional woven polypropylene and constructed from insulating fabric with a breakdown voltage of less than 6 kV.

Type C FIBC Bags

Distinguished by their textile fabric, Type C FIBC bags incorporate a network of conductive tape. This feature allows the bag to be grounded during filling and discharging, effectively preventing hazardous electrical discharges and sparks when properly grounded.

Type D FIBC Bags

Type D FIBC bags are crafted from electrostatic dissipation material. This design helps control explosive discharges without requiring manual grounding, thereby ensuring the safety of individuals in contact with the bag’s surface.

Different kinds of FIBC bag styles

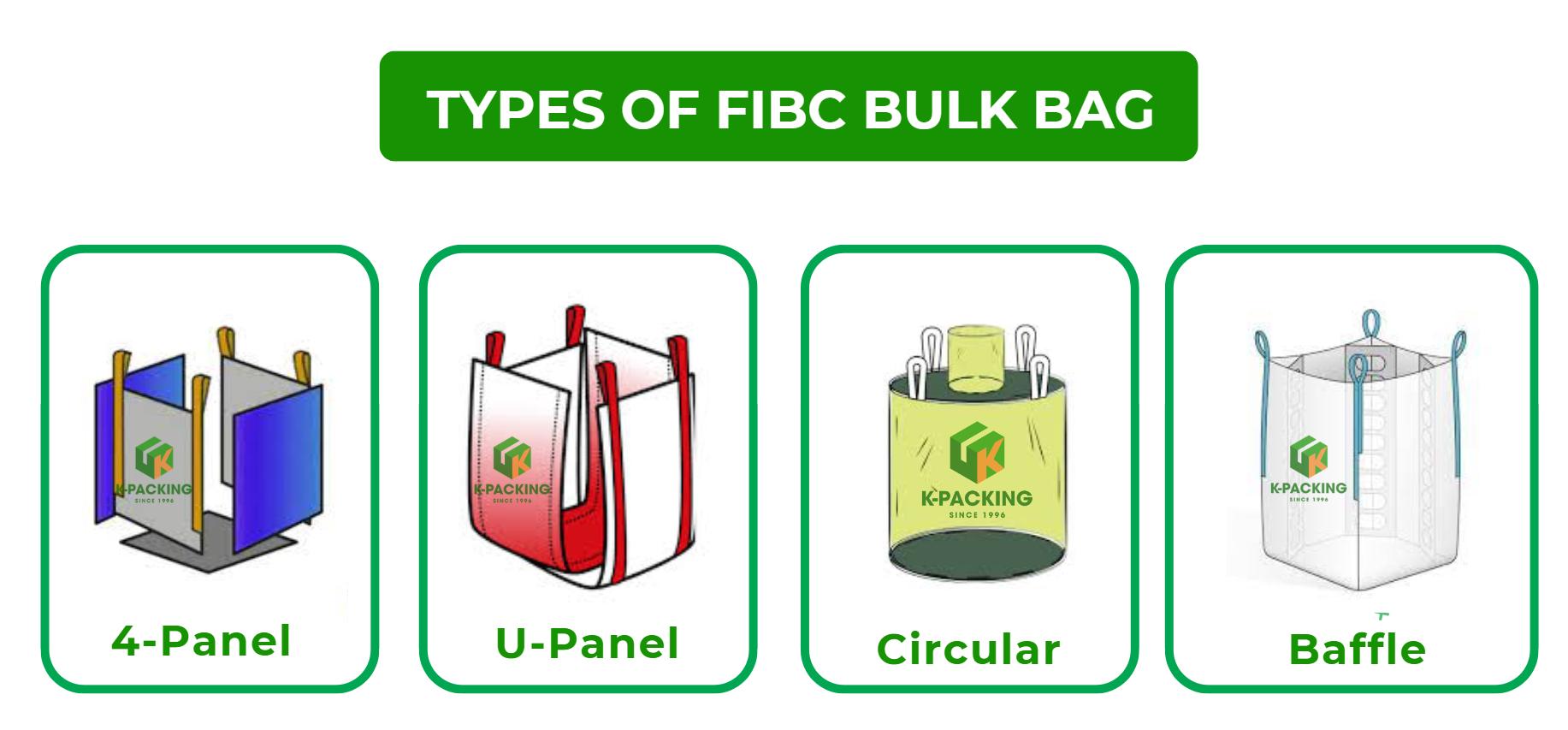

Aside from the four common types, FIBC bags are also classified based on different construction styles:

- 4-Panel: Constructed from four separate panels stitched together along the seams to form the body of the bag, then sewn with a single bottom piece. This design helps evenly distribute weight and stabilize the FIBC bag.

- U-Panel: Cut from a single piece of fabric folded into a U-shape to create two side panels and a single bottom panel, providing better weight-bearing capacity.

- Circular: Constructed from seamless tubular fabric forming a cylindrical shape, minimizing the risk of seam failures and enhancing durability, suitable for containing fine powders.

- Baffle: Incorporates internal baffles or panels sewn into the corners of the bag, forming a square or rectangular shape when filled, reducing bulging and deformation during transportation, especially for powdered materials, improving storage efficiency by up to 30%.

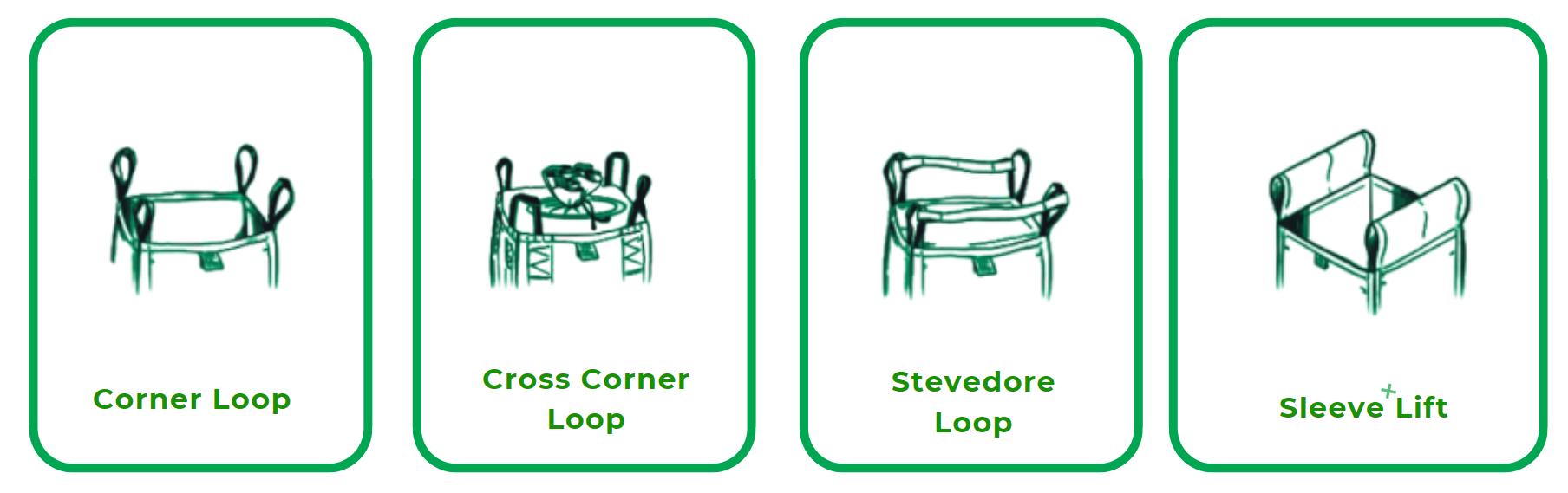

Types of LOOP CONSTRUCTION

Loop construction refers to the way lifting loops or straps are attached to FIBC bags for handling and transportation. Here are the common types of loop construction:

- Corner Loop: Lifting loops are attached to each corner of the FIBC bag, suitable for use with crane hooks or forklift tines, supporting balanced lifting and stable transportation.

- Cross Corner Loop: Lifting loops are attached diagonally across the corners of the FIBC bag, helping distribute the bag’s weight evenly, reducing the risk of tipping over, and facilitating easy attachment and detachment of lifting equipment.

- Stevedore Loop: Additional strap loops are attached along the sides of the FIBC bag, providing extra grip and control during manual handling by workers, along with additional support and control during lifting.

- Sleeve Lift: A sleeve or tunnel integrated into the FIBC bag runs along the sides or corners, ensuring stability and preventing slippage during lifting operations.

TYPES OF FIBC BAGS’ TOP CONSTRUCTION

Top construction refers to the design and arrangement of the upper portion of a FIBC bag, here are the common types of top constructions:

- Open Top: The bag features an open top without any sealing mechanism, allowing for easy and quick loading and unloading of loose materials, suitable for swift access and spillage is not a major concern.

- Duffle Top: It has a cylindrical fabric extension at the bag’s top, which can be closed using drawstrings or straps to secure the contents, providing protection against dust while still allowing easy filling.

- Spout Top with Flap: This type includes a spout at the top covered by a fixed flap secured with drawstrings, allowing controlled pouring into the bag and minimizing spillage, suitable for loose materials.

- Conical Spout Top: Utilizes a conical-shaped spout to control the amount of material poured into the bag, reducing the risk of spillage during discharge, ideal for free-flowing materials such as grains, seeds, or powders.

- Spout Top: Similar to the spout top with flap but lacks the additional flap covering, convenient for loading, unloading, and suitable for cases requiring quick loading and unloading.

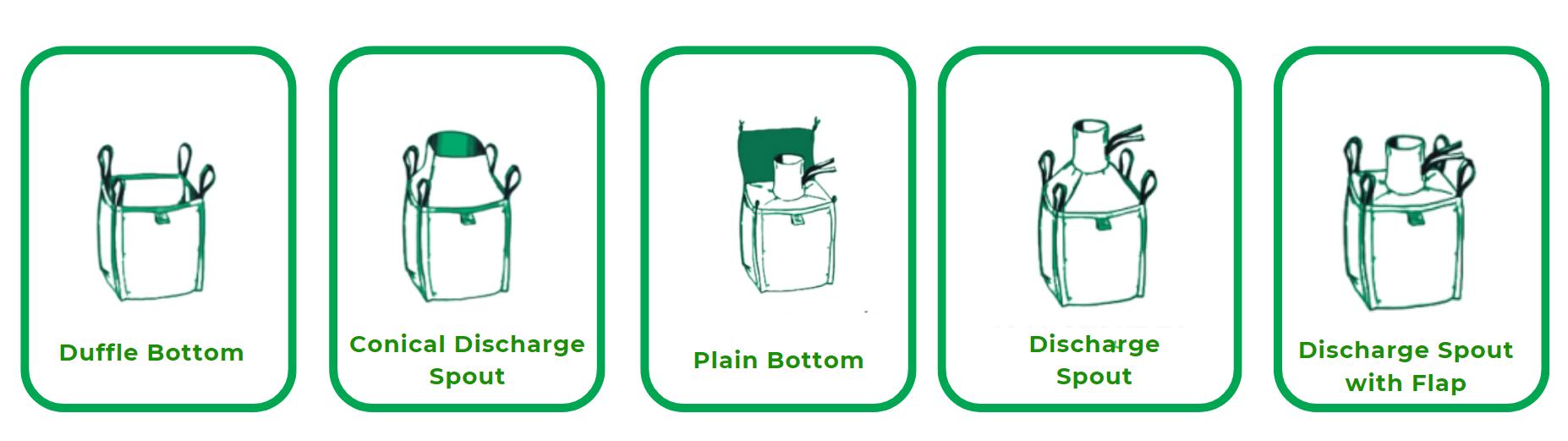

TYPES OF FIBC BAGS’ BOTTOM CONSTRUCTION

Bottom construction refers to the design and arrangement of the lower portion of a FIBC bag, here are the common types of bottom constructions:

- Duffle Bottom: The bottom has a cylindrical fabric extension, allowing for easy material discharge, and can be closed using drawstrings or straps for easy control to prevent spillage of the contents inside.

- Conical Discharge Spout: It utilizes a conical-shaped discharge spout at the bottom of the bag, facilitating easy and controlled material discharge, suitable for materials requiring precise pouring.

- Plain Bottom: It has a flat, uninterrupted bottom without any discharge spout or extension, suitable for cases where materials can be discharged directly from the bottom of the bag in a simple manner.

- Discharge Spout: This type features a standard discharge spout at the bottom of the bag, enabling controlled material discharge and can be closed using closure mechanisms to prevent leakage.

- Discharge Spout with Flap: Similar to the discharge spout, but with an additional flap covering the spout opening to prevent contamination and spillage during storage and transportation.

Which type of flexible intermediate bulk container bags are right for me?

To determine the appropriate type of FIBC bag, you can consider the following criteria:

- Material: Choose FIBC bags with suitable features for the stored material. For instance, chemicals should be stored in safe, anti-static FIBC bags.

- Size: FIBC bags range in size from 500kgs to 2500kgs, so consider the amount of material to optimize storage space.

- Environmental conditions: Some specific needs like preventing soil erosion or landslide require durable FIBC bags. Therefore, select bags with UV protection or moisture barriers.

- Additional features: Depending on your specific requirements, you may need FIBC bags with additional features like moisture protection liners, lifting loops for transportation, or discharge spouts for easy unloading.

Contact our sales team for detailed consultation on the FIBC bag specifications that suit your needs and to receive a quotation.