PP Woven bags are a common type of packaging used in agriculture, food, chemicals, and construction thanks to their durability, high load capacity, and reusability. However, many people are still unsure about the shelf life of PP Woven bags and what to keep in mind when storing and using them. This article will help you understand these points so you can use PP Woven bags more effectively and safely.

1. Do PP Woven bags have a shelf life?

Just like other packaging products and safety equipment, PP Woven bags have a specific shelf life that depends on the quality of the woven fabric, manufacturing process, and storage conditions. When stored properly — in a dry place and away from direct sunlight — PP Woven bags can typically last 3–5 years.

The shelf life does not only indicate how “new” the bag is but also directly affects its load-bearing capacity, seam strength, and ability to protect goods. Expired or weathered bags (damaged by sunlight, heat, or moisture) may become brittle, tear easily, or lose their ability to keep products safe during transportation and storage.

Shelf life & recommended uses by PP Woven bag type:

- Standard PP Woven Bags: 3–5 years under normal conditions — ideal for animal feed, rice, flour, fertilizer, and other bulk agricultural products.

- High-Quality PP Woven Bags: 5–7 years with optimal storage — suitable for branded retail packaging, promotional events, trade shows, and applications where appearance matters.

- PP Film Bags: 5–10 years when properly stored — commonly used for food packaging, medical supplies, and moisture-sensitive products.

- Industrial PP Woven bags: Up to 20 years under controlled conditions — designed for heavy-duty applications such as sand, cement, construction materials, or long-term storage.

2. Key factors affecting shelf life

The shelf life of PP Woven bags can vary because it’s influenced by many factors. Knowing what affects their durability helps you store and use them the right way:

2.1. Material quality

The lifespan of PP Woven bags largely depends on the quality of the resin and manufacturing process. Bags made from high-grade virgin polypropylene with dense, even weaving are more durable and less prone to degradation over time. When UV stabilizers are added, the bags resist sunlight damage, retain their color, and maintain strength longer. In contrast, bags made from low-quality or contaminated recycled material tend to become brittle, tear more easily, and lose load-bearing capacity much sooner.

2.2. Environmental conditions

- Temperature: Store in a cool place, ideally below 50 °C (120 °F), to maintain fiber strength. High heat can soften the fibers and reduce tensile strength.

- UV Exposure: Prolonged direct sunlight breaks down the polymer chains, causing brittleness and cracks.

- Humidity: Excess moisture can lead to mold growth, weaken the woven structure, and cause printed surfaces to smudge or peel.

2.3. Frequency of use

A PP Woven bag can typically be reused around 30 – 50 cycles before replacement is recommended. However, heavy-duty use — carrying sharp objects, exceeding weight capacity, or dragging bags on rough surfaces — will significantly shorten the usable life compared to light-duty applications such as rice, animal feed, or dry goods.

3. How to check the shelf life of PP Woven bags?

PP Woven bags can weaken over time due to sunlight, heat, moisture, or repeated use. A quick check helps ensure they stay strong and safe for storing and transporting goods. Here’s how to know if your bags are still good or should be replaced:

3.1. Inspect the exterior

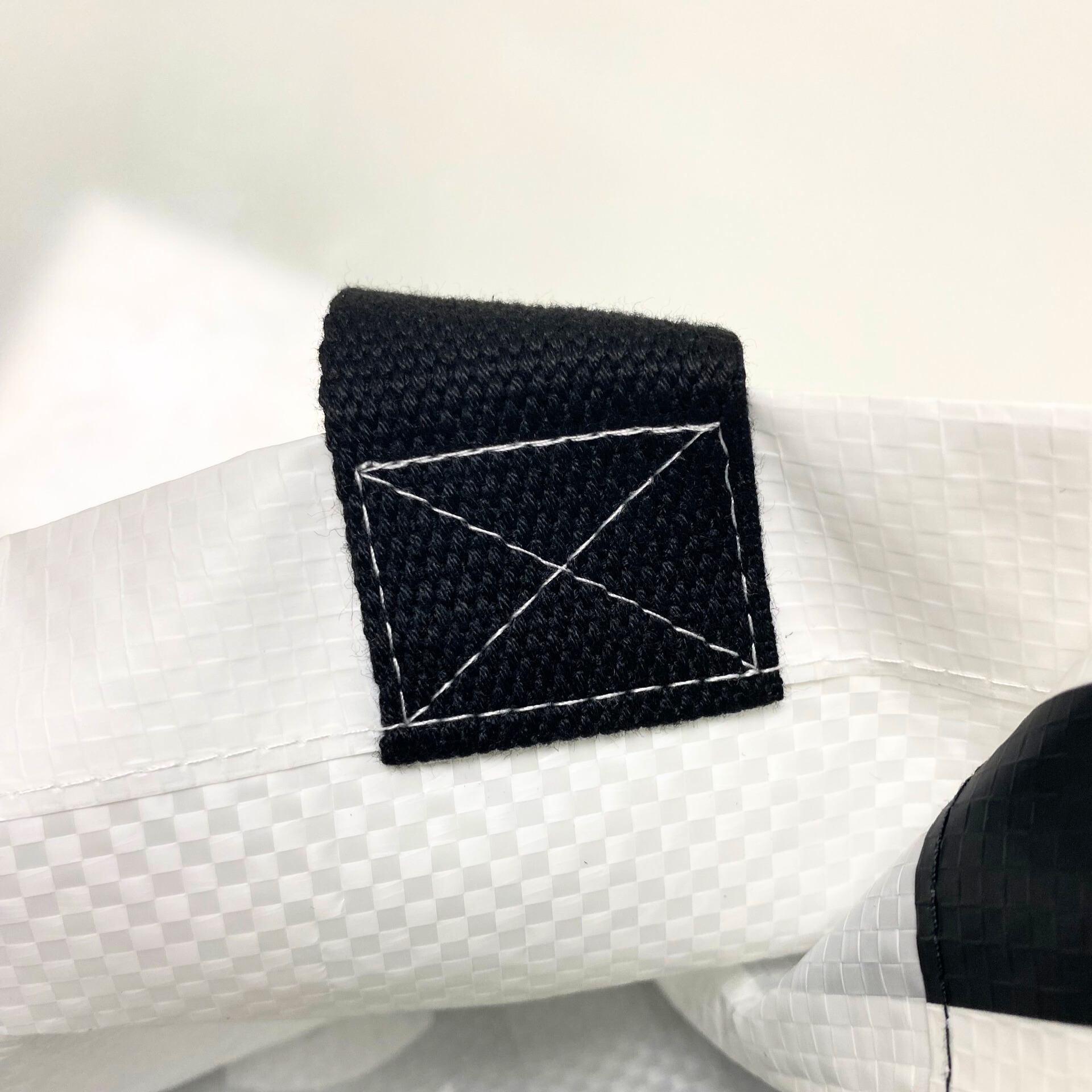

Start by checking the label or tag printed on the bag to find the production date or batch code. This helps determine how long the bag has been in storage. Next, examine the bag’s surface: if the color has faded, the surface has turned cloudy, or there are small cracks, the bag may have passed its usable life. Also look at the seams and woven fabric — if they appear loose, sagging, or tear easily, it’s a clear sign that the bag should be replaced.

3.2. Test basic strength

Gently pull on the bag to see if it tears too easily. A good-quality bag will still feel flexible and resilient, while an expired bag will feel stiff and brittle. Then, try filling it with a small amount of goods to check if it can still carry weight safely. Finally, test its water resistance by pouring a little water to see if the bag remains waterproof or has started to leak.

3.3. Review storage conditions and usage time

PP Woven bags typically have a shelf life of 3–5 years, so if a bag has been stored longer than that, it should be replaced even if it appears intact. Bags that have been left in direct sunlight for more than 3–6 months or stored in hot, humid environments will degrade faster and should be checked carefully before use. If a bag has already been reused more than 30–40 times, it is recommended to switch to a new one to ensure safety.

3.4. Technical testing (optional)

For critical applications or industrial use, technical tests can be performed using specialized equipment such as a tensile tester, hydraulic burst tester, or abrasion tester. These tests can measure whether the remaining strength still meets the manufacturer’s original standards.

4. Key usage notes for PP Woven bags

Proper use and storage of PP Woven bags are essential to maintain their strength, appearance, and safety during transport and storage. The following notes will help you maximize the lifespan and performance of your bags.

4.1. Storage precautions

To extend the lifespan of PP Woven bags, always store them in a cool, dry place away from direct sunlight. Keep the temperature below 50 °C to prevent material degradation and make sure the storage area is well ventilated to avoid moisture buildup. For outdoor storage, use covered areas or UV-protective covers to reduce exposure to sunlight. During transportation, avoid extreme temperatures and keep the storage period under 18 months to maintain quality. It is also important to protect the bags from rodents and pests that can damage the material.

4.2. Handling precautions

Follow safe handling practices to prevent premature damage. Do not exceed the manufacturer’s recommended weight capacity and avoid dragging bags across rough surfaces or exposing them to sharp objects. When lifting, hold the bag securely from the base or use its designated handles. Inspect each bag before use for any tears, punctures, or weakened seams that could compromise safety. When handling chemical or dusty materials, wear appropriate PPE — gloves for rough or contaminated bags, and safety glasses or dust masks when working with materials that generate airborne particles.

4.3. Cleaning and maintenance

Clean PP Woven bags properly to preserve their strength. Hand wash with mild detergent and lukewarm water, or use a gentle machine cycle with cold water for woven bags. Avoid bleach or abrasive cleaners that can weaken the polypropylene fibers. After washing, air-dry the bags completely in a well-ventilated area, away from direct sunlight, to prevent warping or brittleness.

Conclusion

PP Woven bags are a durable, cost-effective, and eco-friendly packaging solution when used and stored properly. Regularly inspecting their condition, following shelf-life guidelines, and maintaining proper storage practices help reduce the risk of product damage, save replacement costs, and ensure safety during transportation. Always choose high-quality PP Woven bags and perform routine checks to maximize their performance and lifespan.