BOPP is one of the most popular plastic films used in packaging today, but many people still don’t know what it is for. In this article, let’s explore with K-Packing what BOPP packaging is, its key features, and why it’s widely used for food, agricultural products, cosmetics, and more.

1. What is BOPP packaging?

BOPP packaging is made from strong, glossy, and clear BOPP film that protects products and makes them more eye-catching. It prints well, resists moisture, and handles heat, making it ideal for food, agriculture, cosmetics, and pharma packaging.

For businesses, BOPP keeps products fresh longer, lowers shipping costs, and helps your brand stand out on shelves. It’s a smart, durable, and cost-effective packaging choice.

2. Why is BOPP used for packaging?

BOPP is used for packaging because it delivers a rare combination of strength, clarity, and cost efficiency. The film is biaxially oriented, meaning it is stretched in two directions to achieve high tensile strength, stiffness, and dimensional stability — so packaging stays durable and resists tearing or puncturing during transport.

Its high transparency and glossy surface make products look premium on shelves, while its surface treatment allows sharp, vibrant printing that enhances branding. BOPP film also provides moisture and oxygen barrier properties and can withstand temperatures up to about 130 °C, helping extend product shelf life.

From a business perspective, BOPP packaging helps reduce product damage, lower logistics costs, and increase customer trust by keeping products safe and visually appealing. Combined with its recyclability and light weight, BOPP is a smart, sustainable solution for food, agriculture, cosmetics, and pharmaceutical packaging.

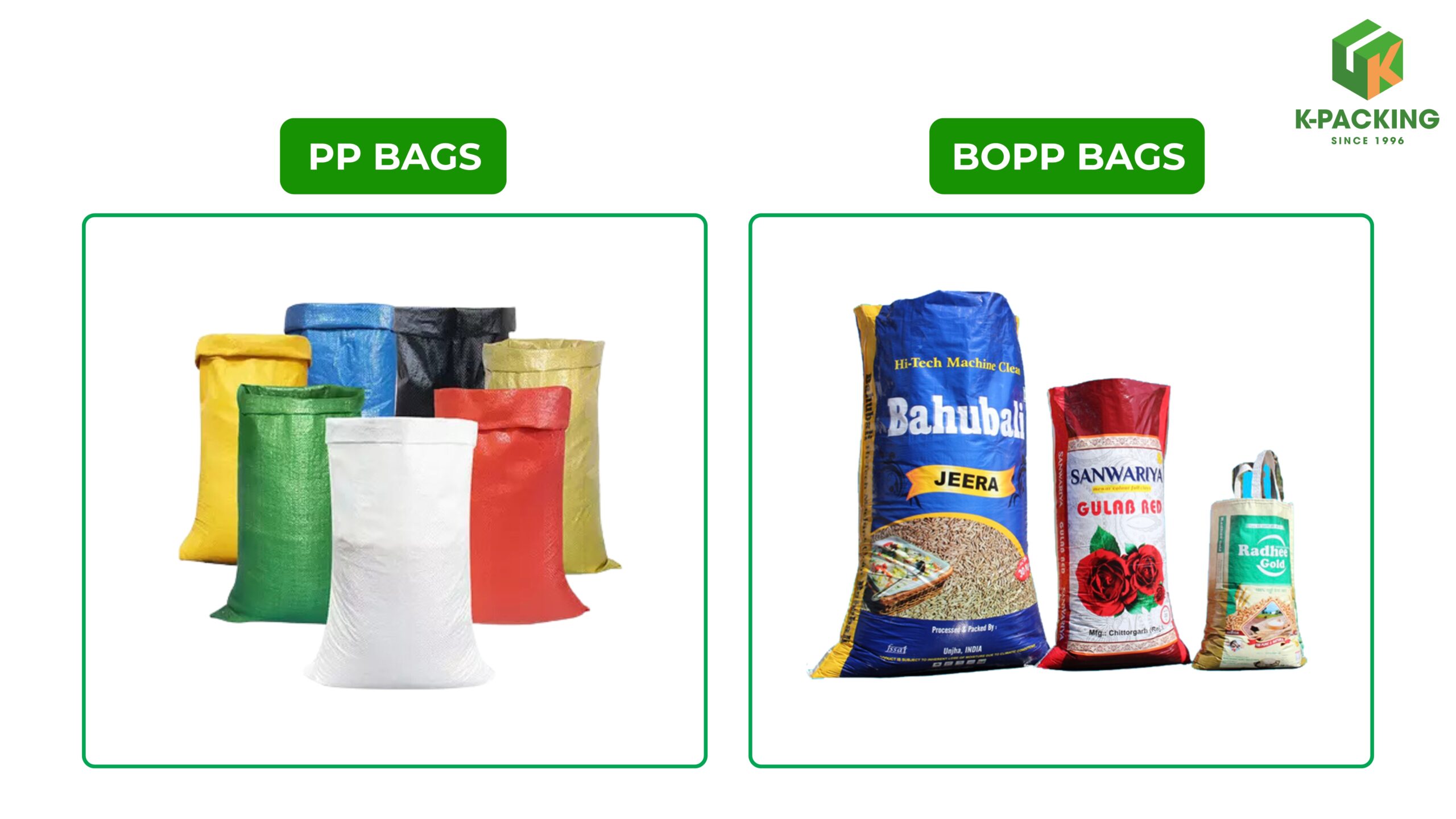

2. Differences between BOPP and other packaging films

BOPP film is one of the most popular choices in packaging thanks to its high tensile strength, glossy finish, and excellent printability. Compared with other films, BOPP is often chosen when businesses need packaging that is protective, visually appealing, and cost-effective:

3.1. Difference between BOPP and OPP

BOPP is biaxially oriented, which makes the film stiffer, more dimensionally stable, and stronger than OPP, which is mono-oriented. This means BOPP packaging resists tearing and keeps its shape during transport and display.

BOPP also offers higher clarity and gloss, giving products a more premium look. Its surface can be corona-treated for better ink adhesion, resulting in sharper and more vibrant printing compared to OPP. This is why BOPP is widely used for snack bags, rice and coffee packaging, and labels where both durability and visual appeal matter.

OPP, on the other hand, is suitable for simpler, lower-cost packaging that does not require as much mechanical strength. Businesses often choose BOPP when they want packaging that enhances product quality and shelf presence.

3.2. Difference Between BOPP and CPP

CPP is a cast film, making it softer, more flexible, and more impact-resistant than BOPP. One of CPP’s biggest advantages is its ability to seal at lower temperatures, saving energy and allowing high-speed packaging lines to run efficiently.

In multilayer packaging structures, CPP is typically used as the inner sealing layer, while BOPP serves as the printed outer layer that adds stiffness and shine. This combination results in a strong, attractive package.

Businesses choose CPP when fast sealing and fold-resistance are priorities. They choose BOPP when they need a package that stands upright, holds its shape, and provides high-quality graphics.

3.3. Difference Between BOPP and PET

PET has very high mechanical strength and can withstand temperatures up to around 260 °C, making it ideal for sterilizable or heat-processed packaging. It also offers superior gas and moisture barrier properties, which extend product shelf life.

However, PET is heavier, more expensive, and harder to tear, which may not be necessary for products that need easy opening. BOPP is lighter, more cost-efficient, and still provides excellent protection for dry foods, snacks, and seeds.

Businesses typically choose PET for premium products requiring high barrier performance or heat treatment. They choose BOPP when they want a lighter, more affordable solution with excellent shelf appeal.

3.4. Difference between BOPP and PE

PE is very soft and flexible, most commonly used as a sealing layer or for simple poly bags. It has lower clarity and gloss compared to BOPP and scratches more easily, which makes it less suitable as an outer printed layer.

In multilayer packaging, PE is often used as the inner sealing layer, while BOPP is used on the outside for printing and stiffness. This combination helps the bag stand up nicely and improves brand visibility on shelves.

Businesses choose PE when they need a low-cost sealing layer or shrink film. They choose BOPP when they want premium-looking packaging that protects the product and strengthens brand recognition.

4. Key points to note when using BOPP packaging

When using BOPP film for packaging, there are several technical points businesses should keep in mind to achieve the best performance and avoid common issues. These cover heat tolerance, film handling, printing preparation, barrier requirements, and recycling considerations:

- Heat resistance:BOPP withstands up to 120–130 °C, ideal for normal heat sealing. Avoid using it in very high or prolonged heat to prevent warping or loss of strength.

- Tension & handling: BOPP is strong but can tear if overstretched. Control film tension during processing to avoid breakage and ensure smooth packaging lines.

- Surface treatment for printing: BOPP needs corona or plasma treatment before printing to make ink and adhesives stick well. Without proper treatment, print can smudge or peel off.

- Barrier & lamination: BOPP has medium moisture and oxygen barrier, so pair it with aluminum foil or barrier film for long shelf life. Always test adhesives and lamination layers to avoid delamination issues.

- Sustainability & applications: BOPP is recyclable as PP, but must be sorted properly. Best for dry food, snacks, and labels; not ideal as inner sealing layers for low-temperature sealing.

Conclusion

By following these key points, businesses can maximize the advantages of BOPP film in packaging — from protecting products and reducing costs to enhancing brand image. K-Packing has outlined the most important considerations for using BOPP effectively and is always ready to provide tailored packaging solutions for your production needs:

Address:

- USA: 7319 N. Loop 1604 E, San Antonio TX 78233, United States

- Angola: Av. Pedro de Castro Van-Dúnem Loy, Luanda, Angola

- Vietnam: 169 Nguyen Ngoc Vu Street, Cau Giay District, Hanoi

Phone: (+84) 855 555 751

Email: info@k-packings.com