Wooden pallets have long been one of the most widely used tools in logistics, manufacturing, agriculture, and retail, serving as the sturdy foundation behind billions of shipments worldwide. Yet many businesses still wonder: what exactly are wooden pallets made of, which types and sizes fit their products best, and are they really worth investing in?

This article will walk you through everything you need to know, from materials and applications to standard sizes, load capacities, and recycling options, so you can decide whether wooden pallets are the right choice for your business.

1. What are wooden pallets made of?

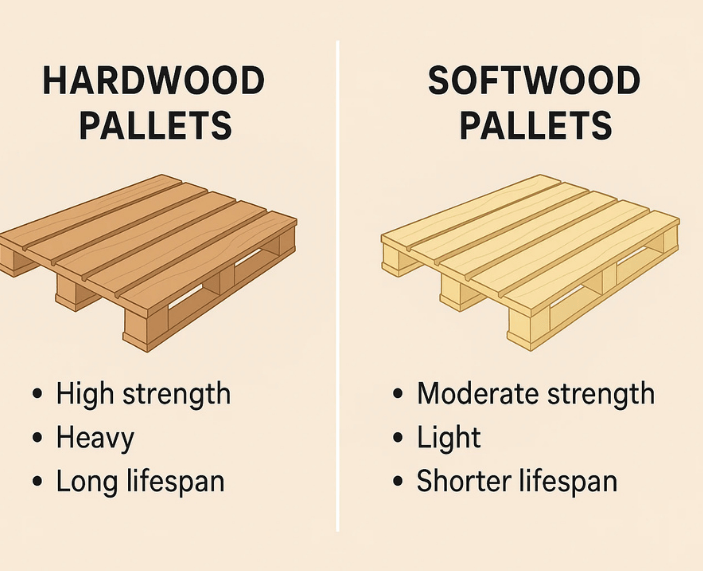

Wooden pallets are primarily made from natural wood, which accounts for more than 90% of all pallets used worldwide. The choice of wood depends on the intended application, strength requirements, and hygiene standards. The two main categories are softwood and hardwood.

1.1 Softwood pallets

Pine is the most common softwood used in pallet manufacturing. In 2021, softwood represented 81% of all lumber used for pallets in the United States.

Softwood pallets are lighter, easier to dry, and more resistant to mold and insect infestation. These qualities make them ideal for industries that require high hygiene standards, such as pharmaceuticals and food & beverages.

1.2 Hardwood pallets

Oak, maple, and oil-bearing woods are preferred for their durability and strength. Hardwood pallets can withstand heavier loads and are less prone to deformation, making them suitable for heavy-duty goods or fragile shipments. In 2021, hardwood accounted for 19% of pallet lumber, equivalent to about 3.5 billion board feet.

A standard wooden pallet consists of three key components:

- Deckboards – Flat wooden planks that form the top and bottom surfaces, providing a stable base for goods.

- Stringers – Long wooden beams that run perpendicular to the deckboards, usually two to four per pallet, serving as the main load-bearing elements.

- Blocks – In block-style pallets, solid wooden cubes are used instead of stringers to support the deckboards from below.

These parts are fastened using carbon-steel nails (ring-shank or spiral), often galvanized to prevent corrosion and improve durability.

2. What are wooden pallets used for?

Wooden pallets are a cornerstone of modern logistics. They provide a durable, reusable, and cost-effective base for handling, storing, and transporting goods across nearly every industry. From farms to factories, and from retail chains to hospitals, wooden pallets help keep global supply chains moving efficiently.

2.1 Agriculture and farming

In the agricultural sector, wooden pallets are used to transport and store fresh produce, grains, coffee beans, rice, cinnamon, and spices. The natural breathability of wood allows air circulation, preventing moisture buildup and rot – a key factor for preserving perishable goods like fruits, vegetables, and flowers.

For example, rice exporters and coffee producers often use heat-treated pine pallets (ISPM-15 certified) to comply with international shipping standards and ensure hygiene in food exports.

2.2 Manufacturing and heavy industry

Wooden pallets are widely used to move industrial equipment, metal parts, spare machinery, and raw materials. Their high load capacity makes them ideal for heavy or irregularly shaped cargo.

In the automotive industry, hardwood pallets carry engines, tires, and steel components, while chemical factories use reinforced pallets to support drums, paints, and industrial liquids during storage and shipment.

2.3 Retail and consumer goods

In the retail sector, pallets simplify bulk distribution to stores and distribution centers. They’re used for packaged foods, beverages, cleaning products, and household items.

Many modern retailers – especially in the organic, eco-friendly, or rustic home decor segment – also reuse wooden pallets as display stands for fruits, wines, or handmade products, adding a natural aesthetic to the shopping environment.

2.4 Pharmaceutical and medical industry

For pharmaceuticals and healthcare products, wooden pallets provide a stable, hygienic base to transport medical devices, bottled drugs, surgical supplies, and disinfectants.

Pallets for this sector are typically kiln-dried and heat-treated, ensuring minimal risk of contamination or insect presence. Their ability to be easily sterilized makes them a trusted choice for hospitals, clinics, and pharmaceutical warehouses.

2.5 Construction and building materials

On construction sites, wooden pallets are indispensable for moving cement bags, bricks, tiles, steel bars, and timber planks. They allow safe stacking, faster loading and unloading, and better site organization.

For example, palletized bricks and tiles can be lifted directly by forklifts or cranes, reducing manual labor and preventing material damage.

3. What size are wooden pallets?

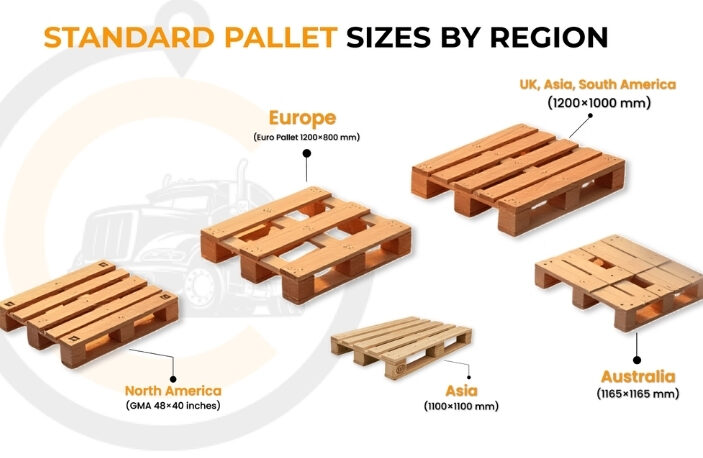

Wooden pallets come in several standardized sizes that suit different industries and regional shipping systems. Choosing the right size ensures safe handling, efficient stacking, and compatibility with forklifts, racks, and transport containers.

3.1 Standard U.S. pallet

The most common wooden pallet size in the United States is 48 x 40 inches (122 x 102 cm), known as the GMA (Grocery Manufacturers Association) pallet. It represents more than 30% of all pallets in circulation nationwide.

This size is widely used in the food, beverage, and consumer goods industries to carry:

- Bottled water, soft drinks, and beer crates

- Canned foods and snack cartons

- Cleaning and household products

Each pallet typically has 3 stringers and 7 deckboards, with an overall height of about 6.5 inches (16.5 cm) — strong enough for stacked warehouse loads.

3. 2 Other common U.S. pallet sizes

| Size (inches) | Industry | Typical products |

| 40 x 40 | Dairy | Milk crates, yogurt packs, cheese boxes |

| 36 x 36 | Beverage | Soda cases, juice bottles, beer packs |

| 48 x 20 | Retail / E-commerce | Mini display pallets, in-store promotion stands |

| 48 x 36 | Paper & roofing | Printing paper rolls, roof shingles |

| 48 x 42 | Chemical | Paint buckets, cleaning liquids, detergent drums |

| 48 x 45 | Automotive | Engines, car batteries, spare parts |

| 42 x 42 | Telecommunications | Cable reels, electrical equipment |

| 48 x 48 | Industrial liquids | Chemical barrels, oil drums, adhesives |

These variations exist to optimize load stability and truck space utilization for each product category.

3.3 International and ISO pallet sizes

Globally, wooden pallets follow the ISO 6780 standard to ensure compatibility in export logistics. The most common dimensions include:

| Size (mm) | Region / Name | Used for |

|---|---|---|

| 1200 x 800 | Europe – Euro Pallet (EUR 1) | Packaged foods, beverages, consumer goods |

| 1000 x 1200 | Asia / UK | Bulk cargo, export goods |

| 1100 x 1100 | Japan / Korea | Electronics, chemicals |

| 1200 x 1000 | Australia / New Zealand | Building materials, agricultural goods |

| 1140 x 1140 | Oceania (ISO standard) | Industrial containers, large drums |

Among them, the Euro Pallet (1200 x 800 mm) is the most widely used across Europe, thanks to its durability, repairability, and regulatory compliance.

4. How much do wooden pallets weigh?

The weight of a wooden pallet depends mainly on its size, type of wood, and moisture level. Most wooden pallets fall between 30 and 70 pounds (13–32 kg), but the number varies following clear rules that reflect how each pallet is built and used.

First, the larger the pallet, the heavier it is. A standard 48×40-inch pallet – the most common in the U.S.- weighs about 44 pounds (20 kg) if made from softwood, while an industrial 48×48-inch pallet used to carry chemical drums or heavy machinery can reach 65 pounds (30 kg) or more. Smaller display pallets used in retail may weigh only 20–25 pounds, making them easier to lift and move by hand.

Second, wood type directly affects weight. Softwood pallets (pine, spruce) are lighter and easier to handle, perfect for food, beverage, and pharmaceutical shipments where hygiene and portability matter. Hardwood pallets (oak, maple) are denser and heavier – around 55–60 pounds (25–27 kg) – and are preferred for automotive or construction materials that demand higher strength.

Third, moisture content changes the weight noticeably. A freshly made pallet with “green” wood is heavier because of retained water. After kiln-drying or heat treatment (as required by the ISPM-15 export standard), the same pallet can lose up to 15% of its weight, becoming lighter, cleaner, and more durable for export use.

In practical terms, a pine pallet carrying boxes of bottled water might weigh just 20 kg, while a hardwood pallet loaded with engine parts or cement bags can exceed 30 kg. This relationship between size, material, and treatment helps logistics teams choose the right pallet – balancing strength, hygiene, and handling efficiency for each industry.

5. What to do with wooden pallets

When wooden pallets reach the end of their first life cycle, they don’t have to go to waste. Because they are made from natural, reusable material, wooden pallets can be reused, recycled, or repurposed in many creative and sustainable ways.

5.1 Reuse in logistics or warehousing

Many pallets remain structurally sound even after several trips. Businesses can inspect, repair, and reuse them for new shipments. In warehouses, slightly worn pallets are often reassigned for domestic transport or in-house storage, especially for light or non-sensitive goods. For example, a pallet used for exporting rice or coffee can later be reused for transporting packaging supplies.

5.2. Recycling for new materials

Damaged pallets are valuable raw materials for recycling. They can be dismantled and turned into new pallets, or processed into wood chips, compost, or biomass fuel. Some recycling centers grind old pallets into mulch for gardening or use them in energy recovery systems for factories. This circular process helps reduce landfill waste and supports low-carbon manufacturing.

5.3 Creative DIY and furniture projects

For smaller quantities, old pallets are popular for DIY projects. People turn them into garden beds, coffee tables, bookshelves, benches, or wall panels. With sanding and a coat of paint, a used pallet can become part of a rustic home decor trend — giving industrial wood a second life in a cozy, aesthetic form.

5.4 Professional collection and donation

When businesses handle large volumes, they can partner with pallet collection services. These companies pick up unwanted pallets, repair or recycle them, and reintroduce them into the supply chain. Another eco-friendly option is donation: community gardens, schools, or small workshops often welcome free pallets for their own projects.

Proper maintenance also extends a pallet’s lifespan. When kept dry, clean, and well-ventilated, a wooden pallet can last 3–5 years and sometimes longer with regular inspection and minor repairs.

In short, wooden pallets are not single-use products. With smart reuse, recycling, or creative transformation, they remain a sustainable, cost-effective resource in both industry and everyday life.

Conclusion

Wooden pallets remain one of the most practical and sustainable packaging solutions in global logistics. Their balance of strength, versatility, and recyclability makes them suitable for nearly every industry – from agriculture and manufacturing to retail and construction.

By understanding the materials, standard sizes, weight, and reuse options, businesses can make smarter choices that reduce costs, improve efficiency, and support a more sustainable supply chain. In short, a well-chosen wooden pallet is not just a base for goods – it’s a foundation for smarter, greener business operations.