As global rice trade expands across humid and variable climates, the question “Are rice bags waterproof?” has become increasingly relevant. Moisture is one of the main causes of rice spoilage condensation inside containers (“container rain”) can lead to mold, clumping, and nutrient loss. According to Clariant (2021), even properly packed grains can deteriorate when water vapor inside sealed containers condenses during long sea transport.

Scientific studies further confirm that poor packaging and humidity fluctuations accelerate rice quality decline, including increased fat acidity and aroma loss over time . In this article, we examine how different bag materials PP woven, BOPP laminated, and PE-lined address these issues and help preserve rice freshness throughout storage and export.

1. What material are rice bags made of?

Modern rice bags are mainly made from polypropylene (PP) – a thermoplastic polymer known for its strength, low moisture absorption, and food safety. This material is ideal for storing and transporting grains because it combines durability, light weight, and cost efficiency.

The main raw material is virgin PP resin, which is non-toxic, odorless, and food-grade safe. It keeps the rice uncontaminated and prevents chemical reactions with the packaging. Manufacturers sometimes mix in calcium carbonate (CaCO₃) to make the fabric stiffer and reduce production costs, or UV stabilizers to protect the bags from sunlight during long-term outdoor storage.

The PP resin is drawn into thin tapes and woven tightly typically at 7×7 to 14×14 tapes per inch to form a strong, flexible fabric. This woven structure gives the bag excellent tensile strength and tear resistance, allowing it to hold 5–50 kg of rice without breaking or deforming.

Woven PP fabric also has very low moisture absorption, which helps protect the rice from humidity and mold. It can withstand high temperatures during filling or sealing, and its smooth, glossy surface is suitable for high-quality printing, making it easy to display branding and product information clearly.

2. Are rice bags waterproof?

Most rice bags are not completely waterproof, but they can be moisture-resistant depending on how they are made. The difference lies in the material composition and the type of surface coating or inner liner used. Standard woven polypropylene (PP) fabric allows limited airflow, while laminated or lined versions provide added moisture protection.

2.1 PP woven bags

Basic woven polypropylene (PP) rice bags are made by weaving thin plastic tapes together. This creates a strong but slightly porous fabric with tiny gaps between the tapes.

These gaps make the bag breathable, allowing air circulation and preventing condensation when rice is stored in dry environments. However, because of this open weave, the bag cannot block water completely. When exposed to rain or placed on wet surfaces, water can slowly penetrate through the fabric.

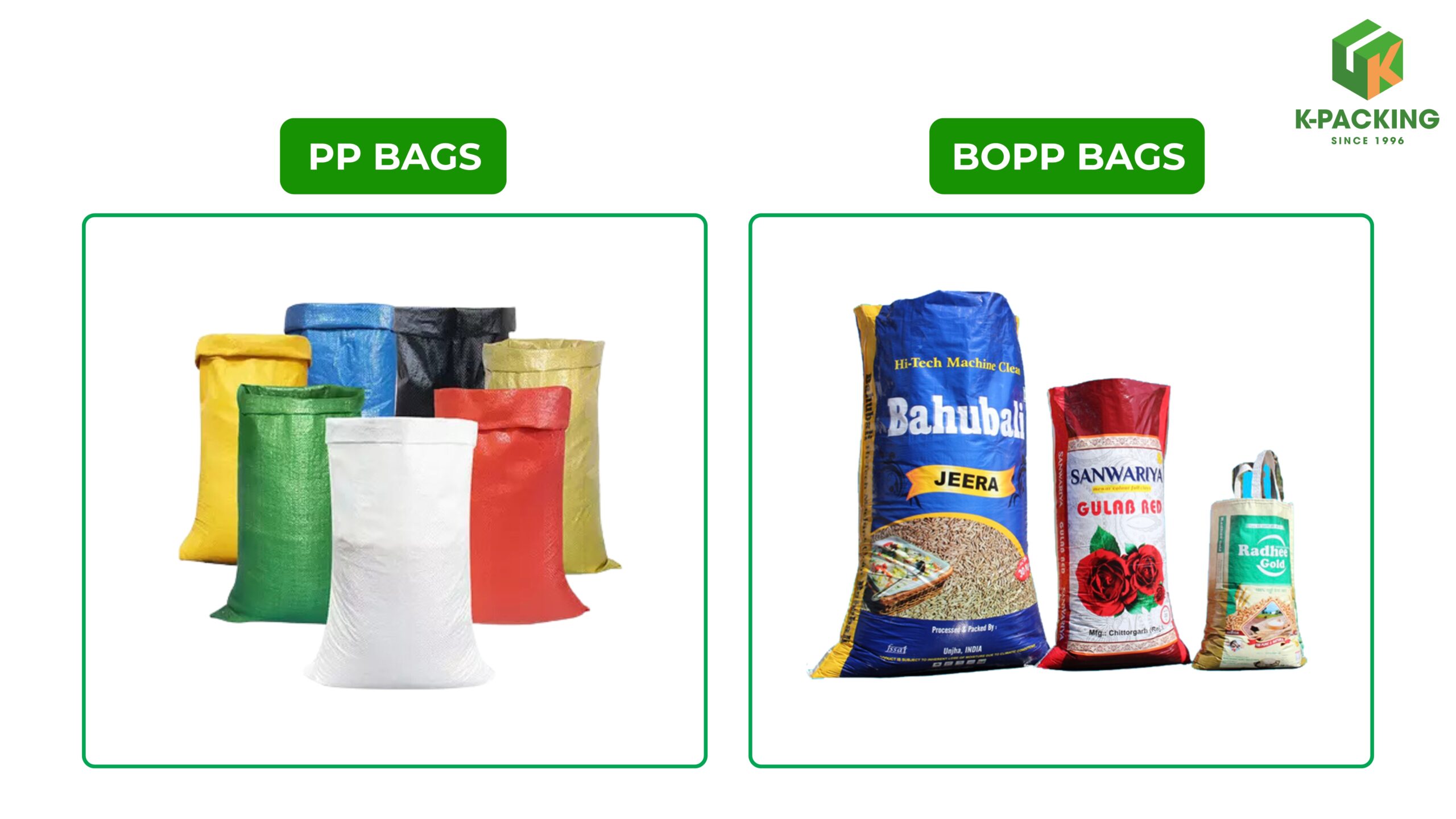

Such bags are suitable for domestic markets, dry warehouses, or short-term storage, where humidity is well controlled. But for exporters or brands that need stronger moisture protection, the next step is to use BOPP laminated bags – a better balance between durability, appearance, and water resistance.

2.2 BOPP laminated bags

BOPP (Biaxially Oriented Polypropylene) laminated bags are woven PP bags coated with a thin BOPP film on the outside. This film acts as a moisture barrier, reducing water vapor penetration while giving the bag a smooth, glossy finish suitable for high-resolution printing. These bags not only protect the rice better but also enhance the brand’s shelf appeal, making them popular for premium retail packaging and export use.

However, BOPP laminated bags are still not fully waterproof, as moisture can enter through the stitching or seams. For exporters who need near-total protection especially in humid climates or during sea freight the next level of solution is PP woven bags with an inner PE liner.

See more: PP Bags vs BOPP Bags: What’s the difference?

2.3 PP bags with PE liner

A polyethylene (PE) inner liner adds a second, sealed layer inside the PP woven structure. This combination makes the bag nearly waterproof, preventing water or condensation (“container rain”) from seeping into the rice. PE liners are essential for export shipments, container transport, and storage in tropical or coastal areas where humidity is high.

Although this option costs slightly more, it offers the most effective protection for long-term storage and international logistics. Many exporters now use BOPP laminated PP bags with PE liners, combining the aesthetic appeal of BOPP with the moisture barrier of PE – achieving both performance and presentation.

3.How to choose the right rice bag for your needs

Choosing the right type of rice bag depends on storage conditions, transport distance, and product positioning. Each structure – PP woven, BOPP laminated, or PP with PE liner – offers a different balance between cost, durability, and moisture protection.

3.1 For dry warehouses and short-term storage

When rice is stored in dry, controlled environments, a standard PP woven bag is usually the most practical choice. The woven structure keeps the rice breathable, allowing air to circulate and preventing mold caused by trapped moisture.

This type of bag is lightweight, economical, and easy to produce in large quantities. It is most commonly used for domestic distribution, bulk packaging, or short-term storage of less than three months.

However, because PP woven bags have no protective coating, they should not be exposed to rain or damp surfaces. If the rice needs better presentation or additional moisture protection, the next step is to move toward BOPP laminated bags.

3.2 For retail and branded products

When rice is sold under a brand or displayed in retail stores, BOPP laminated PP bags are the preferred option. The BOPP film layer adds a moisture barrier while creating a smooth, glossy surface that supports high-quality printing. This combination not only protects the rice but also makes the packaging look premium and professional.

These bags work well for premium rice varieties such as jasmine, ST25, or organic rice, where both product quality and visual appeal are important. They are suitable for supermarket shelves and moderately humid environments, where occasional contact with moisture might occur.

Although the lamination improves resistance to humidity, BOPP laminated bags are not completely waterproof. Water can still pass through the sewing lines or side seams during long transport or storage in coastal climates. In such conditions, the best solution is to use BOPP laminated bags with an inner PE liner.

3.3 For export and humid conditionsr

For export shipments or long-term storage in humid regions, PP woven bags with a PE (polyethylene) inner liner provide the highest level of protection. The inner liner forms a sealed barrier that blocks water and prevents moisture from entering, even during sea transport.

This design is especially effective against condensation and “container rain”, which often occur when containers experience temperature changes. By using the double-layer structure, exporters can keep rice dry and safe throughout long shipping journeys.

To maximize protection, the rice should be dried to a moisture content of 13–14% before packing. Even the best liner cannot prevent mold if the rice itself contains too much water. For international shipments, it is also advisable to include desiccant bags inside the container to absorb excess humidity and reduce the risk of spoilage.

Conclusion

Rice bags differ in how well they resist moisture. PP woven bags are breathable but not waterproof. BOPP laminated bags add moderate moisture protection and a better look. PP woven bags with PE liners offer near-waterproof safety for exports and humid conditions.

Choosing the right type ensures rice stays dry, clean, and high-quality throughout storage and transport. The right packaging helps maintain freshness, prevent mold, and protect the brand’s reputation in every market.