HDPE (high density polyethylene) bags, often called “plastic shopping bags” or “HD bags,” are made from high-density plastic. They have a slightly textured surface, are stronger, and more durable than thin, regular plastic bags. You’ll often see them used in supermarkets, grocery stores, and restaurants to carry food, household items, and daily purchases.In this article, we’ll explore the main advantages, disadvantages, and common applications of HDPE bags – helping you understand when and why to use them effectively.

1. Characteristics and properties of HDPE bags

HDPE bags are widely used thanks to their strength, durability, and safety for packaging. To understand where they are suitable — and where they may have limitations – it’s helpful to look at both their physical and chemical properties:

1.1. Physical characteristics of HDPE bags

HDPE bags are well-known for their excellent rigidity and strength. They can carry heavy loads without tearing easily, which makes them highly suitable for supermarkets and retail packaging. However, this rigidity also means they are less flexible and may not be the best option when a soft, stretchable bag is preferred – for example, for irregularly shaped items that need more give.

The surface of an HDPE bag is slightly rough and textured, with moderate transparency and gloss, and it usually comes in a natural milky-white color. This neutral look works well for many uses, but it offers limited aesthetic appeal compared to clear, glossy bags that showcase products better on display.

Compared to regular PE, PP bags, HDPE bags are noisier and crease more easily, producing the characteristic “rustling” sound when handled. While they are lightweight and have a superior load-bearing capacity, their stiffness can make them less comfortable to carry for long periods, especially with sharp-edged contents.

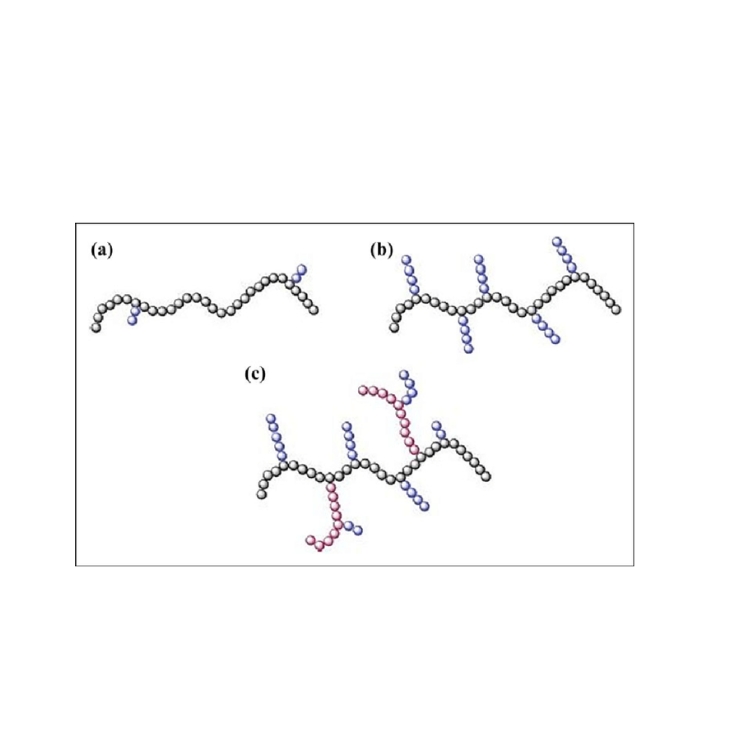

1.2. Chemical properties of HDPE ags

One major strength of HDPE bags is their resistance to diluted acids, alkalis, oils, and other common liquids, making them safe for food and household use. On the downside, this durability can also make them slower to break down in the environment, raising concerns about plastic waste and sustainability if not properly recycled.

They provide excellent water resistance, keeping goods dry even in wet conditions. However, their low gas permeability can be a drawback for packaging fresh produce, as it may accelerate spoilage by trapping moisture and limiting airflow.

Finally, HDPE bags can withstand extremely low temperatures – down to about -117°C – without cracking, making them perfect for cold storage. But they are less suitable for high-heat applications, as they can soften or deform when exposed to very hot liquids or environments.

2. Advantages of HDPE bags

HDPE bags are known for being affordable and convenient, making them a common choice for everyday packaging needs. While they are not as versatile as some alternatives, they still offer several practical benefits worth noting:

2.1. Quality-related advantages

HDPE bags have decent durability and resist tearing when used properly, helping protect goods during storage and transport. They are considered safe for food contact, meeting hygiene standards and containing no harmful substances. Chemically, they remain stable at room temperature, resisting oxidation and most common reactions. Thanks to their insulating properties, they can also serve in basic technical applications such as temporary wire insulation, protective liners in production, or packaging to shield electronic components from moisture and dust.

2.2. Economic and practical advantages

Because HDPE bags are inexpensive to produce, they are sold at a lower price compared to many other types of bags, making them suitable for high-volume, everyday use. Their surface allows for basic printing of logos or product information, though the results are usually simple rather than highly detailed. In addition, HDPE bags are recyclable and can be manufactured in various colors, which helps reduce waste when proper collection and recycling processes are in place.

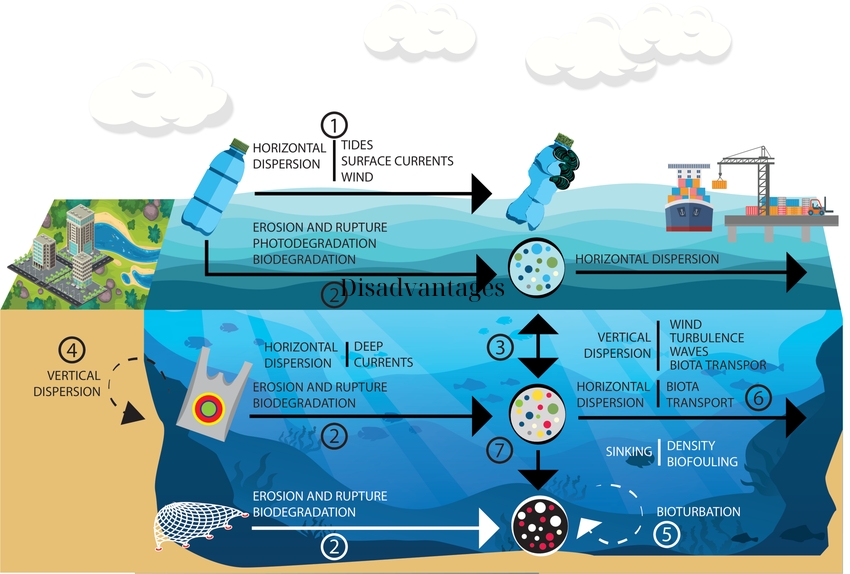

3. Disadvantages and risks of HDPE bags

Although HDPE bags are affordable and convenient for many daily uses, they also come with several limitations and potential risks. Understanding these drawbacks helps businesses and consumers choose packaging that better fits their needs, safety standards, and long-term sustainability goals:

3.1. Serious environmental concerns

One of the biggest challenges with HDPE bags is their environmental footprint. When they break down mechanically, they release microplastics and even nanoplastics, which are harmful to aquatic life. Unlike biodegradable materials, HDPE can remain in the environment for hundreds of years, contributing to global plastic pollution. Under UV exposure and friction, they fragment into tiny pieces that are very difficult to collect and remove completely.

3.2. Potential health risks

HDPE bags carry a risk of chemical migration into food, especially when exposed to high temperatures. Recycled HDPE bags, if not properly processed, may contain additives or contaminants above safety limits. They also have the tendency to absorb and retain odors from the surrounding environment, which can affect the quality of the stored goods.

3.3. Technical limitations

Compared to LDPE, HDPE bags are less flexible, more prone to cracking when overstretched, and may deform at temperatures above 80 °C. When compared with PP woven bags, HDPE bags have lower strength, cannot withstand as many reuses, and have a shorter service life. Compared with cotton fabric bags, HDPE is cheaper and lighter but lacks premium aesthetics, is less eco-friendly, and does not align well with brands aiming for a sustainable or high-end image. In addition, the textured surface can scratch easily under rough handling, reducing its visual appeal.

4. Applications of HDPE bags

Thanks to their low cost and convenience, HDPE bags are still widely used in many countries, especially for high-volume daily packaging needs. Their affordability makes them a practical option for businesses and consumers alike, although they continue to raise concerns about waste generation and environmental impact. Below are some of the main applications where HDPE bags are most commonly found:

4.1. Retail & supermarket shopping

HDPE bags are the go-to choice in supermarkets and convenience stores because they are cheap and easy to use. They carry groceries, clothing, and everyday goods efficiently.

However, because they are often single-use, they create a large amount of plastic waste. Many retailers now switch to kraft paper bags for dry items or cotton/canvas bags for frequent shoppers – reducing plastic pollution and presenting a greener brand image.

4.2. Food & freezer packaging

Food-grade HDPE bags are widely used to store vegetables, meat, fish, and frozen goods because they keep products fresh and resist moisture.

Still, they are not biodegradable and can add to long-term waste. Businesses seeking eco-friendly solutions may choose PLA bio-bags, corn-starch compostable bags, or even cold-resistant paper boxes for premium items.

4.3. Waste collection

HDPE trash bags are cheap and waterproof, making them practical for home and industrial waste. But they also make up a big share of landfill plastic. Compostable trash bags, PBAT-based bags, or paper bags for dry waste are increasingly preferred to reduce environmental impact.

4.4. Industrial & agricultural use

HDPE bags are strong enough for fertilizers, seeds, and construction materials, and even used as soil covers or pond liners. For better durability and branding, PP woven sacks or kraft paper composite bags are often chosen since they can be reused multiple times and allow better printing – lowering total consumption and waste.

Conclusion & Notes on using HDPE bags

HDPE bags are present in almost every sector – from consumer goods to industrial packaging – thanks to their durability, water resistance, and food safety. However, to reduce plastic waste and environmental impact, businesses and consumers should gradually switch to alternative materials such as paper bags, fabric bags, or biodegradable bags, depending on the specific application and technical requirements.

If HDPE bags must still be used, prioritize recyclable types, reuse them whenever possible, and ensure proper waste sorting to support recycling efforts. Whenever conditions allow, consider adopting more sustainable packaging solutions to meet packaging needs while helping protect the environment in the long run.