To understand more about the packaging production process and tips for using as well as preserving packaging properly, let’s follow our article below.

How is PP woven packaging manufactured at our factory?

Step 1: Our packaging factory discusses with the customers about ideas.

To know and understand more about the needs of customers exactly, our packaging company will contact and exchange important information about packaging which customers want to buy including:

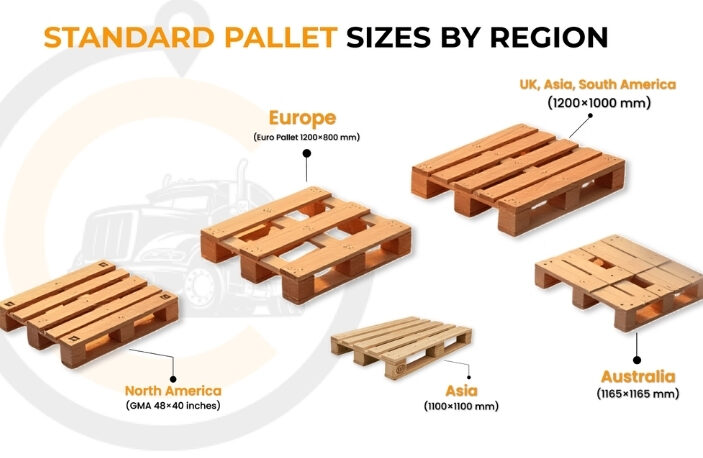

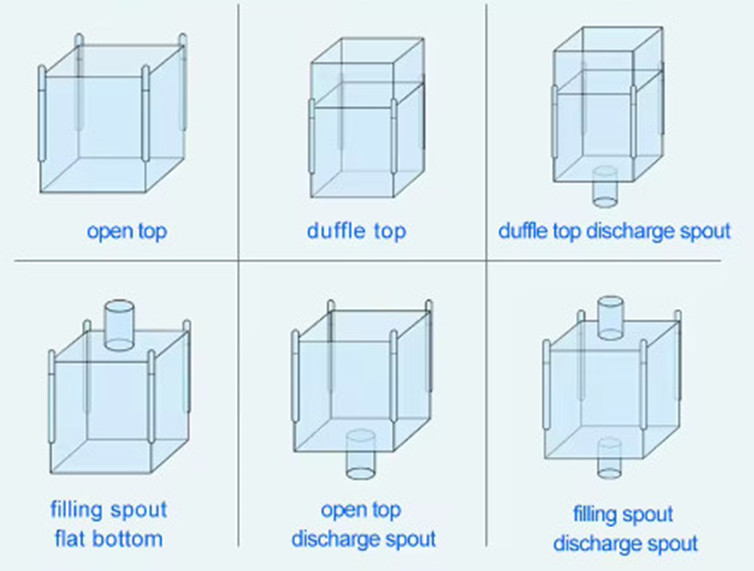

- Packaging specifications

- Requirements on quality standards of packaging

- Intended use of packaging

- The quantity and the deadline for the packaging manufacturing process

- Payment methods and payment conditions

Due to the information provided by customers, our factory will have the basis to consult the most suitable products related to the material, size, content, image, number of color, and the best production technique.

In addition, if the customers already have designs, the first step will still be very crucial for our factory to give useful advice and suggestions to customers.

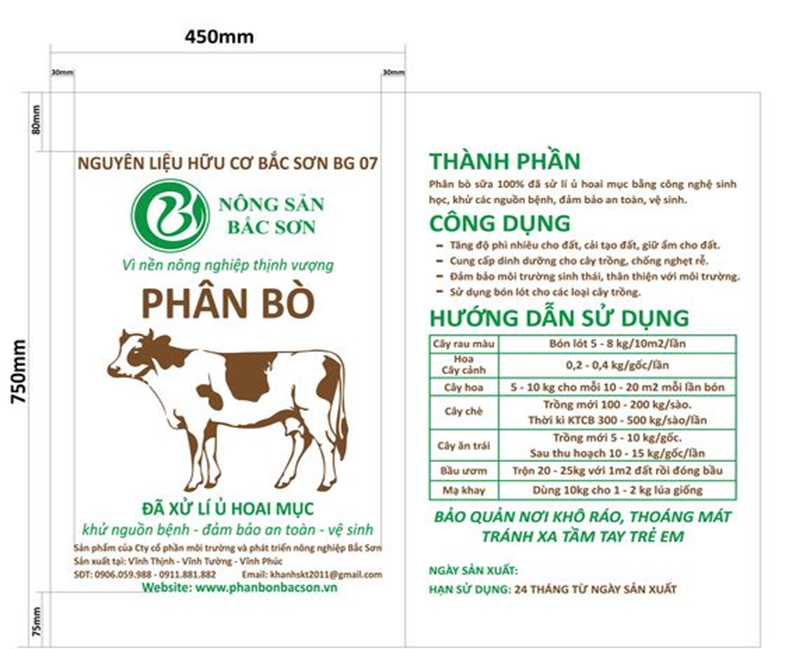

Step 2: The factory designs packaging products including the structure and images.

According to customers’ requirements, our packaging factory will plan to design the structure, shape, information, and photos of products on appropriate design software. This not only helps customers visualize the packaging actually, but also judges the capacity, bearing capacity when stacked, as well as measures the feasibility of hanging or displaying merchandise on shelves.

Step 3: The factory produces sample products.

After the second step, our company will make a practical design pattern and adjust suitably to ensure the shape, information, color, capacity, bearing of the product as requirements. Through this step, our factory can check the viability of the packaging, and need to request customers to approve the samples as well as color before mass production.

Due to printed samples, the factory not only minimizes errors and risks during producing packaging involved in product specifications, but also saves a lot of time and the labor. Moreover, the customers will be satisfied with the quality of products absolutely.

Compared to fast printing, proof printing is significantly superior because the color resolution mode of proof printing is similar to offset printing.

Step 4: The factory carries out production orders.

-

Conduct PP plastic spinning.

First, to create fibers, put plastic beads into the hopper of specialized equipment. Then, the vacuum machine will transfer the plastic granules into the machine and perform melting heating, the plastic granules and additives will melt and flow out of a small hole. From that, the plastic film is formed through a cooling system.

Then, the plastic film is put into the cutting machine to form PP plastic fibers with a width of about 2-3mm. The heating unit will stabilize and feed the yarn into the winding machine to form yarn rolls in preparation for the production of PP plastic packaging.

-

Weaving fabric to form packaging.

The plastic fibers will be fed into a circular loom consisting of 6 shuttles. The weaving machine will wind the yarn and weave it into a tube. Then, roll it into a large roll of PP fabric packaging fabric.

-

Coating PE film of PP woven packaging.

Our factory will weave the film on PP woven packaging as required. The PP plastic fabric will be passed through a PE film coating machine to coat a thick layer of about 30 grams/m2. After finishing coating, the fabric is rolled up for use in the printing process of PP plastic bags.

-

Perform printing according to customer requirements.

After coating, the factory will use Flexo technology for printing. Designs from customers are applied in this process, in which the printing mold is created from Polymer or rubber.

-

Cut finished PP woven packaging products.

After printing, the PP fabric roll will go through the folding system and be cut into pieces according to the shape and customer’s requirements.

-

Sewing packaging.

Then, the PE plastic packaging layer is put into the sewing machine to fold the bottom of the PE plastic bag, creating stability for the bottom of the bag. If requested by the customer, PE plastic bags will be inserted into PP plastic bags. This ensures maximum moisture resistance for the product inside.

-

Check, package products, and deliver to customers.

Before packaging, the final product will be thoroughly inspected. The factory will remove packaging products that do not meet quality standards such as wrinkled, wavy paper, scratched printing surfaces, etc. based on certain quality standards. This step ensures that the packaged product when delivered to the customer can achieve the highest accuracy.

Step 5: Listening to customer feedback and improving the quality of products.

Customer feedback will be important information to help the factory improve products, service quality, delivery schedule, etc. This is one of the necessary steps for the factory in the process to develop, and enhance to bring better experiences to customers.

Notes you need to know

Uses of PP woven packaging

- Store and transport agricultural products such as rice, seafood, feed, fruits, etc., fertilizer products, and animal feed. Woven PP packaging products used in the agricultural industry often include PP woven bags, chemical PP bags, etc.

- Food packaging packages food, does not cause harm to users, is highly durable, and has good preservation ability.

- Application in geotechnical engineering: PP woven packaging is a useful tool for irrigation projects, roads, railways, ports, mines, buildings, etc to filter, drain, isolate and leak-proof.

- Use for natural disaster prevention: due to its waterproof properties, woven PP packaging is highly effective in flood prevention.

How to preserve PP woven packaging properly

- Use the correct packaging for the prescribed load.

- Store packaging in dry, cool places, avoid moisture and avoid direct sunlight for long periods of time because these factors can significantly affect the mechanical durability of PP woven bag products.

- Arrange the packaging neatly, stack no more than 10 layers and the force must be evenly distributed.

As an exclusive Japanese manufacturer, K-Packing is one of the reputable manufacturers specializing in Jumbo bags, bags for animal feed, agricultural products and fertilizers with more than 25 years of experience. in the industry. Located at 169, Nguyen Ngoc Vu Street, Cau Giay District, Hanoi, Vietnam, our specialty is manufacturing high-quality, low-cost packaging products for manufacturing businesses and traders. commerce, logistics companies, local governments, mining companies and are distributed worldwide.

As a leading packaging manufacturer in Vietnam, we can meet all customer requirements for products, are responsible for coming up with ideas and standard production according to customer specifications. K-Packing is committed to providing absolute customer satisfaction, we guarantee to deliver high quality packaging products worldwide, helping us stand out from our competitors.

In particular, K-Packing’s packaging products are manufactured to meet Japanese standards, so we ensure product quality absolutely meets European standards such as ISO 9001-2015; ISO 14001:2015. Refer to K-Packing product samples at Our Website

If you have any questions, feel free to contact us at +84 85 555 5751.