Bulk chemicals such as fertilizers, plastic resins, and industrial powders are easily affected by moisture, contamination, and static hazards. Without the right packaging, they may lose quality, pose safety risks, and harm a company’s reputation.

FIBC bags provide a strong and reliable solution with large capacity, liners for moisture control, and certified designs for hazardous goods. They help businesses protect product integrity, ensure compliance, and earn customer trust. In the following sections, we will explore how to safeguard these chemicals effectively with FIBC bags.

1. Choosing the right FIBC bags

FIBCs (Flexible Intermediate Bulk Containers) are the leading choice for bulk packaging in the chemical industry. With a capacity of 500 to 2,000 kilograms, they are suitable for fertilizers, plastic resins, industrial minerals, and detergent powders.

Each chemical requires a different level of protection. Fertilizers such as urea, ammonium nitrate, and potassium chloride must be kept dry to avoid clumping. Plastic resins like PP, PE, and PVC granules need packaging that prevents contamination. Fine powders such as silica, calcium carbonate, and titanium dioxide are hygroscopic and require strong barriers against moisture.

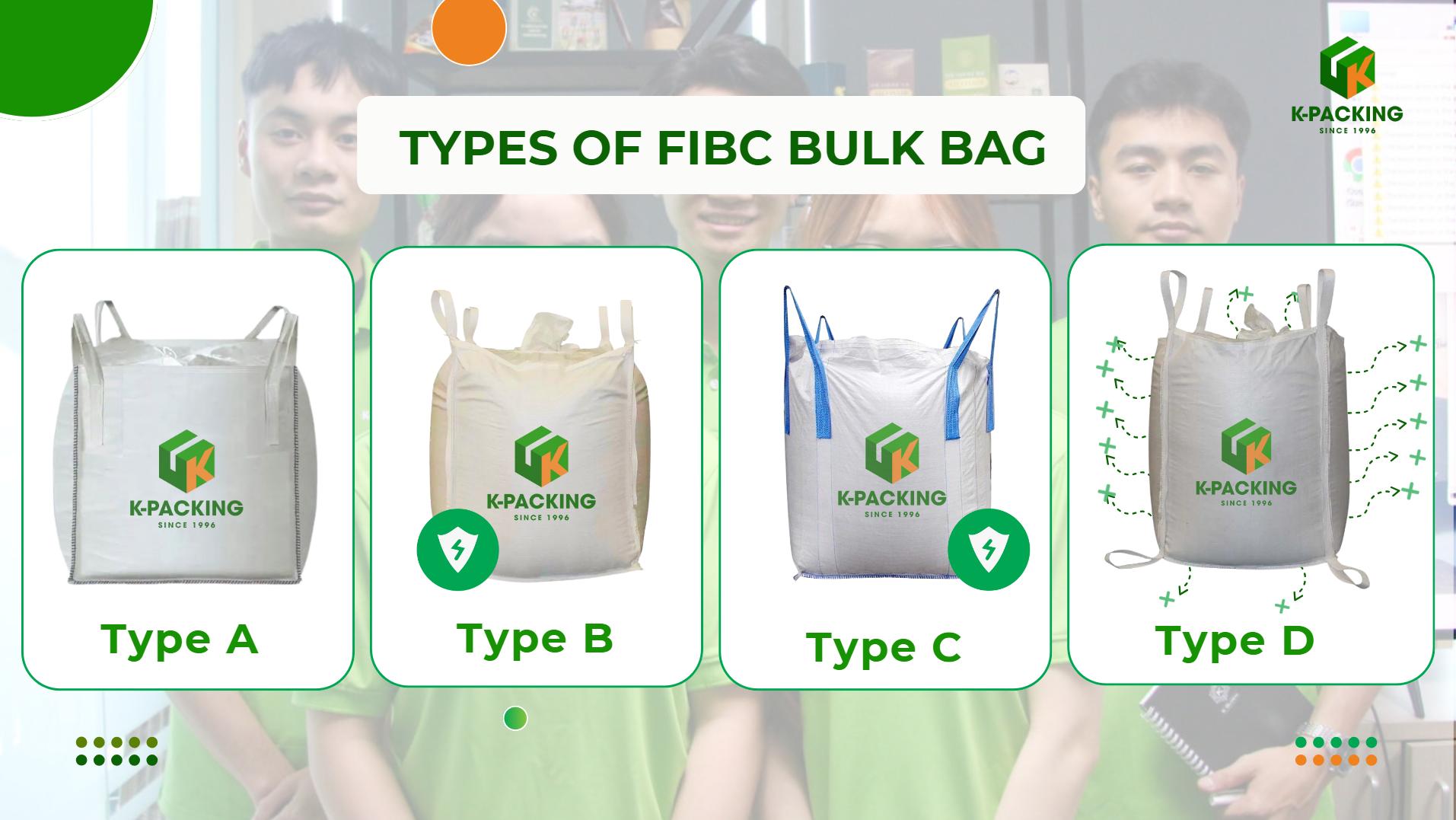

For these sensitive materials, Type C or Type D anti-static FIBCs are recommended to eliminate electrostatic hazards. Hazardous substances like ammonium nitrate must be packed in UN-certified FIBCs. To ensure safe handling, businesses should use bags that meet the safety factor ratio of 5:1 for single-use or 6:1 for multi-use.

Bulk chemicals like fertilizers, resins, and powders are vulnerable to moisture, dust, and static hazards. Without proper packaging, quality and safety are at risk – see [FIBC Bulk Bags: Definition, Types, Specification, Uses.

2. Preparing chemicals before packing

Before packing, every chemical must be conditioned to remain stable. Fertilizers are dried and screened to prevent caking during storage. Ammonium nitrate is highly sensitive and should be handled in cool, dust-free environments.

Plastic resins must be protected from dust and foreign particles, as even small contaminants affect their quality. For titanium dioxide and silica, liners made of PE or aluminum are essential. These liners block oxygen and humidity, which would otherwise reduce the effectiveness of the powders.

3. Packing process

Chemicals should be filled into FIBCs through a top spout, preferably with a closed, dust-free system. This setup reduces dust exposure, protects workers’ health, prevents cross-contamination, and eliminates the risk of combustible dust hazards. It also keeps the bag exterior clean, which is important for handling and transport.

For moisture-sensitive or fine powders such as fertilizers, silica, or titanium dioxide, a liner inside the FIBC is strongly recommended. The liner creates an airtight barrier against oxygen and humidity, preventing clumping, degradation, or loss of chemical stability. Although liners add cost, they ensure long-term product quality and make the bag suitable for export or extended storage.

After filling, the liner should be sealed – heat sealing offers the most secure closure – before the outer FIBC is stitched tightly. This double closure prevents leakage and protects against fine dust escaping during handling. Clear labeling with product name, hazard class, and batch information is essential, both for safety and to comply with international transport regulations.

4. Storage and handling

FIBCs should always be stored on pallets, not directly on the ground. Warehouses must remain dry, cool, and well-ventilated.

Fertilizers degrade when exposed to moisture or heat. Plastic resins are less sensitive but should be kept away from UV light and dust. Powders such as silica and titanium dioxide are extremely vulnerable to humidity and require lined FIBCs plus humidity control.

During handling, forklifts or cranes must be used with the lifting loops. Bags should never be dragged or pierced. For extended storage, desiccants can be added to stabilize the environment.

5. Transportation

During transport, chemicals must be separated according to safety regulations. Ammonium nitrate, for example, must not be shipped together with flammable goods.

Plastic resins should travel in clean, dry containers to avoid contamination. Fine powders like silica or titanium dioxide must be secured to prevent shifting. Moisture protection, including desiccants, is often required for long journeys.

Containers themselves must be dry and ventilated. In tropical or humid regions, lining the container with protective sheets is strongly recommended. All shipments must comply with UN transport codes, and proper hazard labels and MSDS documents must always be included.

Conclusion

FIBC bags are one of the most effective ways to package bulk chemicals. They combine high capacity, safety, and compliance with international standards.

By choosing anti-static bags for powders, UN-certified models for hazardous substances, and lined versions for hygroscopic materials, businesses can maintain product quality and safety.

Following safety factor standards of 5:1 or 6:1 guarantees secure handling. This not only protects the goods but also helps businesses preserve their reputation and meet global customer expectations.