Laminated bags are trusted by many businesses for their durability and moisture resistance. They keep products safe, look professional on store shelves, and help reduce plastic waste — making them a smart choice for today’s sustainable market.

1. What are Laminated bags?

Laminated bags are multi-layer composite bags made by bonding a base fabric (PP woven, non-woven, canvas, or jute) with a lamination film such as BOPP, PE, or aluminum foil. This structure combines the strengths of each material, resulting in bags that are strong, moisture-resistant, and feature a smooth surface for high-quality printing and a premium look.

As consumers demand more sustainable packaging and products need better protection during transport, laminated bags have become a smart solution. They help businesses reduce product damage, enhance brand visibility with vibrant printing, and create a professional image. Customers also enjoy receiving sturdy, attractive bags that can be reused many times — helping cut plastic waste and improving the overall shopping experience.

2. Classification of Laminated bags

Laminated bags can be classified in different ways, but the most common is by base material and lamination type. This makes it easy to choose the right bag for durability, printing quality, and product protection.

2.1. By base material

- BOPP Laminated PP Woven Bags: Made from woven PP fabric laminated with BOPP film, these bags are highly durable, tear-resistant, and resistant to water, dust, and UV rays. Commonly used for animal feed, seeds, fertilizers, and cement – ideal for heavy loads and outdoor storage.

- Kraft Paper Laminated PP Woven Bags: Combining woven PP fabric with kraft paper, these bags provide excellent moisture protection and keep products fresh. Perfect for agricultural products (rice, corn), sand, cement, and dry food, ensuring clean and dry storage.

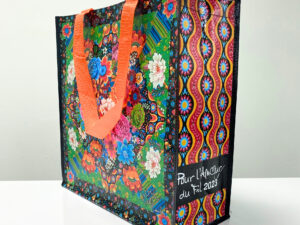

- Laminated Paper Bags: Crafted from 200–300gsm art paper laminated with PP film, these bags offer a premium surface with sharp, vibrant printing. Available in gloss, matte, soft-touch, or metallic finishes, with options like hot foil stamping, embossing, and spot UV. MOQ starts from just 250 bags, making them ideal for gifts, events, and premium brand packaging.

2.2. By lamination type

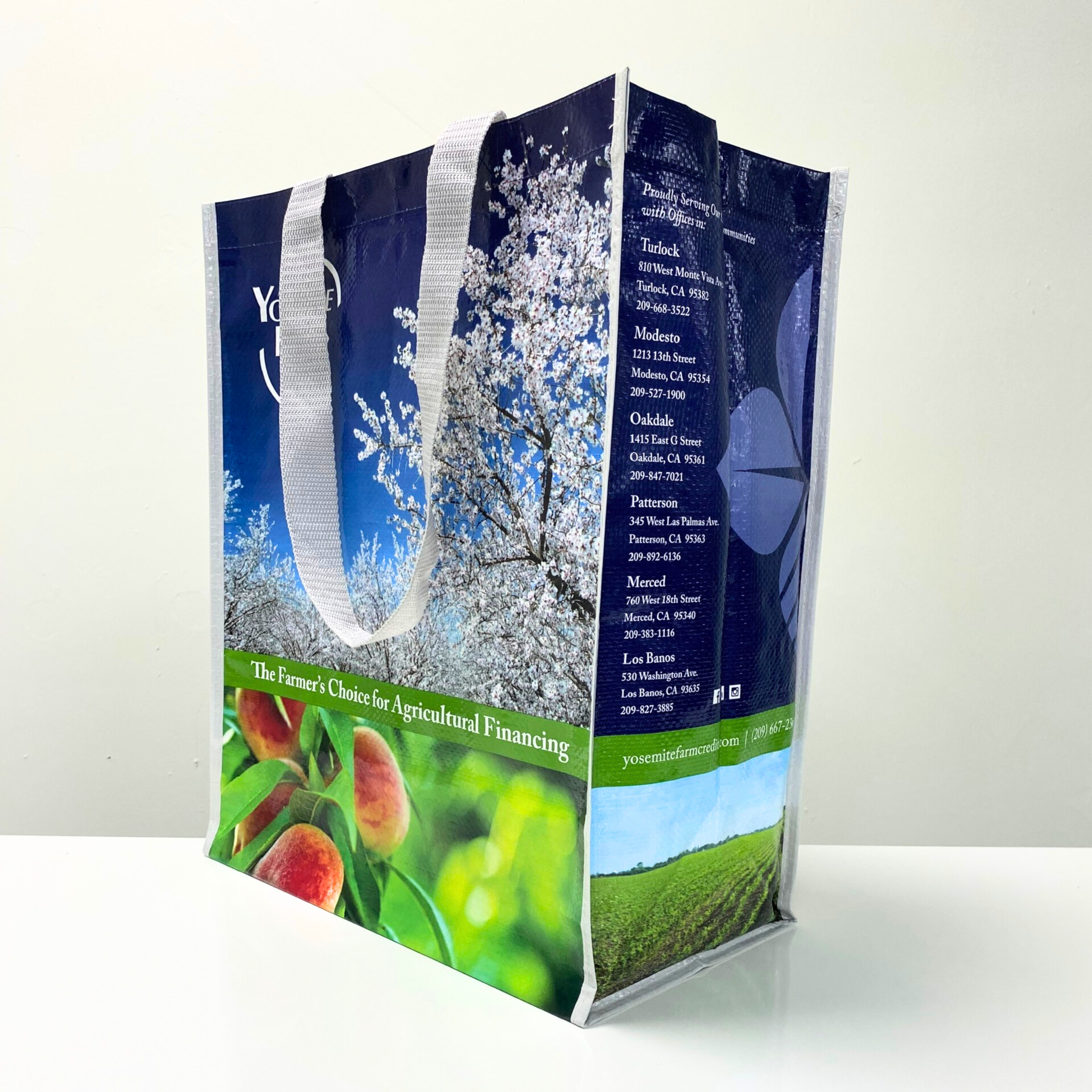

- Transparent Lamination: A clear film is directly laminated onto the fabric, providing moisture resistance while allowing the product inside to remain visible. This option is more cost-effective and ideal for packaging where contents, labels, or colors need to be seen.

- Colored Lamination: Uses pre-colored film to give the bag a vibrant, premium appearance with sharp, high-quality printing. Although it has a higher cost, it enhances brand image and delivers a more upscale look.

3. Benefits of Laminated bags for businesses

- Better product protection: Multi-layer construction keeps products safe from moisture, dust, and damage during storage and transport.

- Boosted brand image: Smooth laminated surfaces allow vibrant, sharp printing that makes packaging stand out and strengthens brand recognition. Premium finishes like gloss, matte, or foil stamping add a high-end look.

- High durability & reusability: Strong structure resists tearing and punctures, allowing multiple uses and supporting sustainability by reducing waste.

- Versatile applications: Suitable for agriculture, food, construction, and retail. Customizable in size, material, and lamination type to fit product needs.

- Cost efficiency: Durable packaging reduces product loss and returns, while lightweight design saves on shipping and storage costs.

4. Practical applications of Laminated bags

Thanks to their durability, moisture resistance, and premium look, they not only protect the product but also make the brand appear more professional. Here are the most common applications of laminated bags:

4.1. Agriculture

Laminated bags keep animal feed dry and fresh, preventing moisture and pests while preserving nutritional value during long-term storage. For seeds and fertilizers, they resist chemical damage, maintain seed viability, and make handling and transportation safer and easier.

4.2. Food industry

Ideal for packaging rice, flour, sugar, and other dry goods. The moisture barrier preserves freshness, prevents contamination, ensures food safety, and extends shelf life — reducing losses during distribution.

4.3. Construction industry

Perfect for cement, sand, and other building materials that require strength and moisture protection. Laminated bags withstand heavy loads and harsh environments, keeping materials in optimal condition during transport and storage.

4.4. Retail & shopping

Premium laminated bags create a luxurious shopping experience for customers at boutiques, fashion stores, or jewelry shops. Their sturdy construction and sharp printing elevate brand image while offering reusability, helping reduce waste.

5. Key Points to onsider when buying Laminated bags in bulk

Price matters, but the cheapest option isn’t always the best. Poor-quality bags can damage products, delay shipments, and lead to higher costs later:

- Material & Layer Structure: Choose the right base material (woven/non-woven PP, kraft, canvas) and lamination (BOPP, PE, foil) with proper thickness to ensure moisture resistance, tear strength, and product protection.

- Printing & Branding: Check print quality and finishing options (gloss, matte, embossing) to make sure your packaging is durable and represents your brand well.

- Strength & Load Capacity: Review tensile strength, tear resistance, and weight capacity to prevent bag failures and product loss during transport.

- MOQ, Pricing & Lead Time: Consider minimum order quantity, bulk discounts, and delivery timelines — a low price isn’t worth it if late delivery disrupts your business.

- Supplier Reliability: Work with reputable suppliers who offer on-time delivery and clear policies for handling defective or incorrect shipments.

7. Why choose K-Packing for Laminated bags?

K-Packing is a leading manufacturer in Vietnam, providing strong, moisture-resistant laminated bags that combine durability, premium printing quality, and sustainability — ideal for agriculture, food, construction, and retail industries:

- Superior protection: Multi-layer construction with BOPP, PE, or foil lamination protects contents from moisture, dust, and UV exposure, keeping products safe during storage and transport.

- Customizable branding: Choose your preferred size, color, material, lamination type, and high-quality printing (gloss, matte, soft-touch, metallic) to showcase your brand and stand out on shelves.

- Certified quality: Manufactured in ISO 9001:2015 & ISO 14001:2015 certified facilities, meeting global packaging, safety, and food-contact standards.

- Cost – effective: Direct factory pricing saves 10–15% on bulk orders, helping you reduce total packaging costs.

- Fast production & delivery: 7–15 day production lead time with dependable worldwide shipping. For DHL shipments, you benefit from up to 50% off freight charges thanks to our status as a major agent — helping you cut logistics costs while ensuring on-time delivery.

📧 Request a Quote Today: info@k-packings.com

📞 Hotline: (+84) 855 555 751

Address:

USA: 7319n. Loop 1604 E, San Antonio TX 78233, United States

ANGOLA: Av. Pedro de Castro Van-Dúnem Loy, Luanda, Angola

VIETNAM: 169 Nguyen Ngoc Vu Street, Cau Giay District, Hanoi