Even a small spark of static electricity can quietly damage a microchip or circuit. Known as Electrostatic Discharge (ESD), this invisible reaction costs the electronics industry billions each year. Anti-static bags were developed to stop such damage by safely controlling and dispersing electric charges.

Beyond protection, these bags are required by international standards like ANSI/ESD S541 and IEC 61340-5-1, ensuring that all sensitive components are handled safely. They keep products reliable, reduce costly repairs, and maintain quality throughout the supply chain. Let’s see how they work and why they matter.

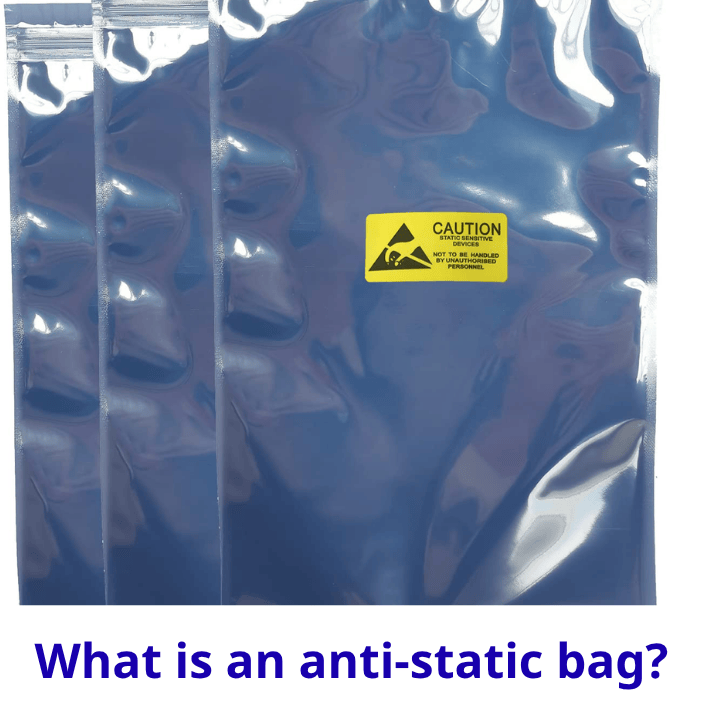

1. What is an antistatic bag?

An anti-static bag is a specially designed packaging material that prevents and dissipates static electricity. Static charge is often generated when two materials rub against each other, and the sudden discharge – known as Electrostatic Discharge (ESD) – can easily damage sensitive electronic components such as chips, transistors, and circuit boards. Even a tiny spark invisible to the eye can destroy or weaken these parts permanently.

In terms of structure, anti-static bags are typically made from plastics like polyethylene or polyester, combined with anti-static additives that allow gentle dissipation of electric charges. Higher-grade versions include a thin metallic layer that creates a Faraday cage effect, blocking external electric fields. This layered design ensures full protection during packaging, storage, and transportation of electronic components.

Anti-static bags usually come in two recognizable colors: pink for dissipative bags and silver for shielding bags. The color helps operators quickly select the correct type in Electrostatic Protected Areas (EPA). By protecting delicate electronics from unseen ESD damage, anti-static bags have become an essential standard in modern electronics manufacturing and logistics.

2. Why anti-static bags are important?

Electrostatic discharge (ESD) is one of the leading causes of damage to electronic components during manufacturing, assembly, and shipping. A sudden discharge as small as a few volts can destroy or weaken microchips, transistors, or integrated circuits, leading to costly product failures. Industry estimates suggest that ESD-related losses in the electronics sector reach hundreds of millions to billions of dollars each year.

By using anti-static bags, manufacturers can prevent both immediate and hidden damage. Immediate damage occurs when a component fails instantly after an ESD event, while hidden damage can slowly reduce performance and reliability over time. Anti-static packaging ensures components arrive at their destination functioning as designed, protecting both product quality and brand reputation.

In addition to reducing financial loss, anti-static bags are also part of compliance and quality assurance systems in modern factories. They are required under international standards such as ANSI/ESD S541 and IEC 61340-5-1, ensuring that every step of handling—from assembly lines to storage and transport—meets ESD control requirements.

3. How anti-static bags work?

Anti-static bags protect electronic components by controlling and neutralizing static electricity before it can discharge and cause damage. The materials used in these bags are engineered to either dissipate or block static charges, keeping the electric potential around sensitive devices stable and safe.

Most pink anti-static bags work by incorporating additives that make the plastic slightly conductive. These additives allow electric charges to move slowly across the bag’s surface and safely discharge into the surrounding air or a grounded surface, preventing any sudden static buildup.

By contrast, metallic shielding bags use a multilayer structure that includes a thin aluminum layer. This creates a Faraday cage effect, which blocks external electric fields and shields the contents from ESD coming from outside sources. Together, these mechanisms ensure that the stored components remain protected both from internal charge buildup and from electrostatic discharges generated elsewhere.

4. Types of anti-static bags

There are several kinds of anti-static bags, each designed for different levels of electrostatic protection. The most common types include dissipative bags, shielding bags, and moisture barrier bags, which are selected based on the sensitivity of the components being packed and the handling environment.

Dissipative bags, often recognized by their pink color, are made from polyethylene blended with anti-static agents. They prevent static charges from building up on the surface of the bag but do not block external discharges. These bags are ideal for use inside Electrostatic Protected Areas (EPA) where static sources are already controlled.

Shielding bags, usually silver or metallic, have multiple layers that include a conductive aluminum film. This structure forms a Faraday cage, protecting the contents from both internal and external static discharge. A more advanced version is the moisture barrier bag, which adds humidity protection for long-term storage or shipment of sensitive semiconductors and circuit boards.

5. Applications of anti-static bags

5.1 In electronics manufacturing

Anti-static bags are essential in the production and assembly of electronic components. They are used to package, handle, and transport delicate parts such as printed circuit boards (PCBs), semiconductors, microprocessors, LEDs, and memory modules. During manufacturing, even minimal static charges can permanently damage these devices.

By enclosing them in dissipative or shielding bags, manufacturers maintain a controlled ESD-safe environment that meets industry standards like ANSI/ESD S541 and IEC 61340-5-1.

5.2 In warehousing and long-term storage

In storage facilities, static electricity can accumulate due to dry air, low humidity, or constant movement of materials. Anti-static bags help maintain component integrity by preventing charge buildup during long-term storage. Moisture Barrier Bags (MBB), a specialized type of anti-static bag, are especially useful for semiconductors and chips that are sensitive to both ESD and humidity.

They are often combined with desiccant packs and humidity indicator cards to provide full protection under JEDEC J-STD-033 guidelines.

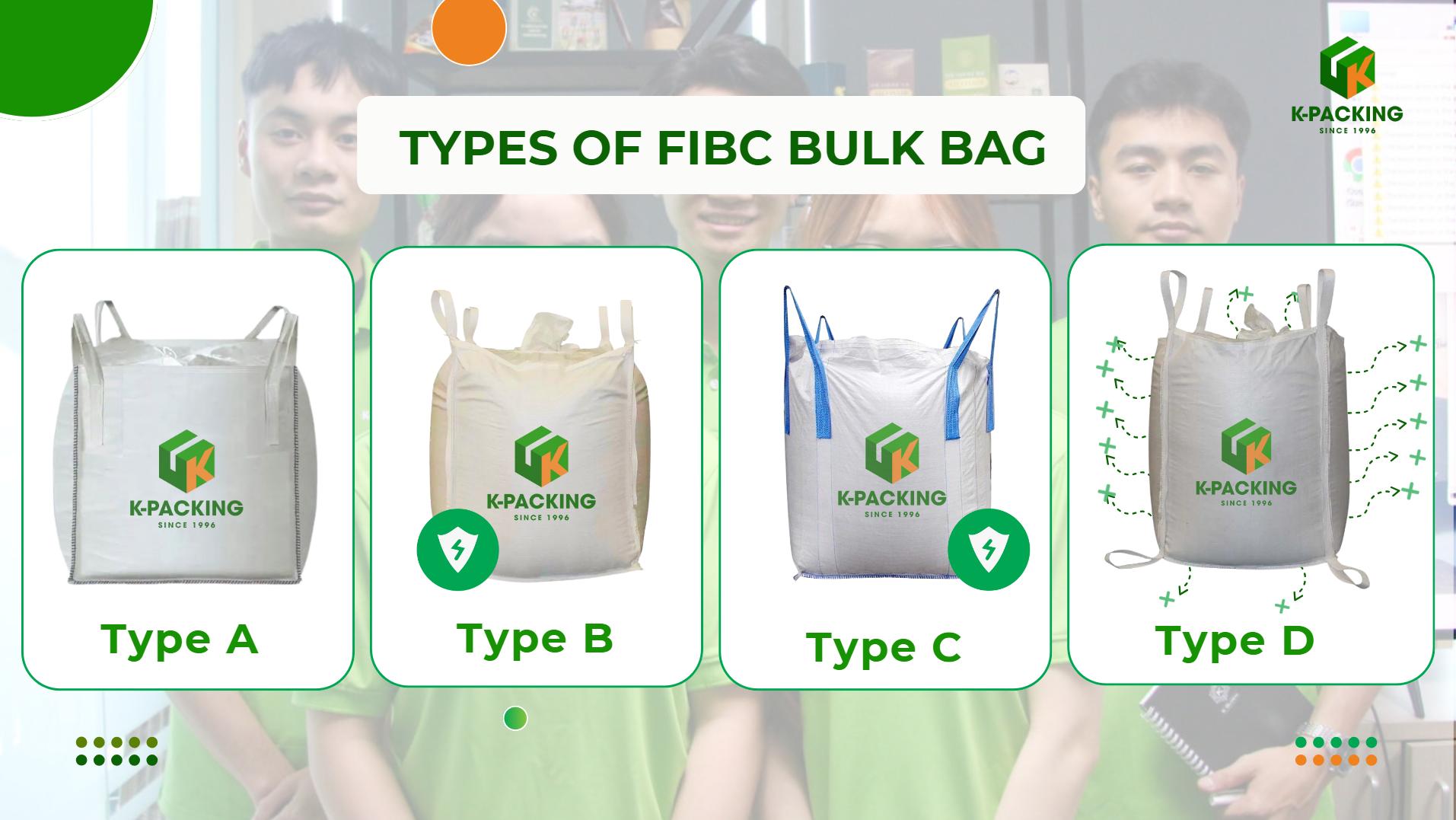

For larger-scale applications, such as bulk storage or transport of electronic components and powders, anti-static FIBC (Flexible Intermediate Bulk Containers) are also used. These industrial-grade woven bags are designed to dissipate or ground static charges safely, preventing sparks during filling, discharging, or handling operations.

Depending on the protection level required, FIBCs are classified as Type B, C, or D, with Type C and D offering the highest level of electrostatic safety through grounding or dissipative yarn technology.

5.3 In packaging and transportation

During shipping, products are exposed to vibration, friction, and changing weather conditions that can generate static electricity. Using anti-static bags minimizes this risk by shielding electronic devices from both internal charge buildup and external ESD sources.

For high-value components or export shipments, companies often use metallic shielding bags with Faraday cage protection, ensuring that the items remain fully functional upon delivery to assembly lines or end customers.

Conclusion

Anti-static bags are essential for protecting sensitive electronic components from electrostatic discharge (ESD). By preventing charge buildup and blocking external electric fields, they ensure microchips, PCBs, and other delicate parts remain safe and fully functional.

From basic pink dissipative bags to advanced metallic shielding and moisture barrier bags, these materials have greatly reduced product failure and financial loss in electronics manufacturing. In larger-scale applications, anti-static FIBCs also provide safe bulk storage and transport for ESD-sensitive materials.

Choosing the right type of anti-static packaging is a smart investment in quality and reliability. It not only protects valuable components but also ensures compliance with international standards such as ANSI/ESD S541, IEC 61340-5-1, and JEDEC J-STD-033.