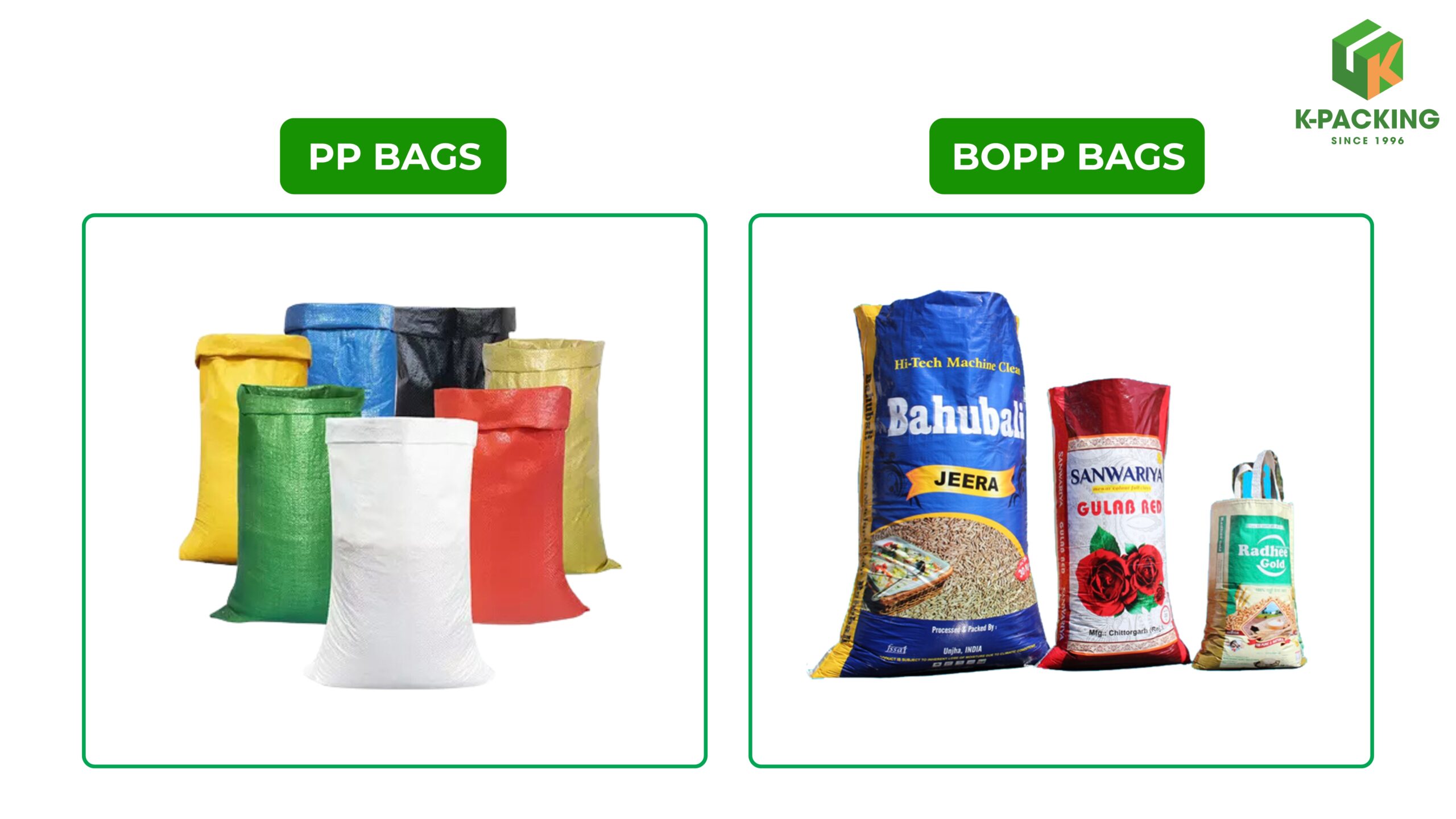

PP Bags and BOPP Bags: What’s the difference?

Polypropylene woven bags, commonly known as PP bags, have been present in our lives for some time. Although the material has undergone several changes since its beginning, it hasn’t fully met the innovative aspirations of woven bag manufacturers.

Are you in the hunt for new packaging options and discovered BOPP bags? You might be wondering if there’s any difference, or if it’s just a new term of the same material. Both types of bags use woven polypropylene, but there’s one main distinction between them. Keep reading to learn the key differences between PP and BOPP bags.

What are PP Bags?

Polypropylene (PP) is a flexible thermoplastic polymer, employed across numerous industries due to its special characteristics, including:

- Light and strong: PP has a high strength-to-weight ratio, making it perfect for robust packaging solutions without additional bulk.

- Moisture protection: PP’s hydrophobic nature makes it ideal for moisture-resistant packaging solutions.

- Chemical resistance: PP resists many acids, bases, and solvents, protecting product safety and packaging integrity.

- Eco-friendly: PP is entirely recyclable, supporting sustainable packaging practices and lessening environmental harm.

What are BOPP Bags?

Biaxially Oriented Polypropylene (BOPP) is a specialized variation of PP that goes through a process known as biaxial orientation. This technique stretches the PP film against the machine direction as well as against the cross direction, yielding material with enhanced qualities such as:

- Enhanced strength: The biaxial orientation process boosts tensile strength and puncture resistance, offering superior protection for goods.

- Superior clarity: BOPP films provide outstanding transparency, perfect for packaging that requires clear product visibility.

- Better barriers: BOPP films offer improved resistance against water vapor, oxygen, and aroma, preserving product freshness.

- High-quality printing: BOPP films provide an excellent surface for printing, making them great for packaging with detailed graphics and branding needs.

Difference Between PP Woven Bags And BOPP Bags

At first glance, it can be challenging to differentiate between the two since they look identical. However, the distinction becomes clear when you touch them. The main difference is that PP woven bags feel soft, while BOPP bags have a brittle texture.

Other differences are clearly listed in the table below:

| ASPECT | PP BAGS | BOPP BAGS |

| Manufacturing | Polypropylene fabric is woven and can be laminated for strength | Follows the same process as PP bags initially but is later laminated on both sides with BOPP films |

| Material | PP woven fabric | PP woven fabric but includes a lamination of biaxially oriented film |

| Properties | Low water retention – Laminated PP fabric improves water resistance for some uses | Better water resistance – Ideal for packaging flour by keeping it safe from moisture |

| Size of bags | A wide range of sizes: large sacks, bags with handles, and jumbo bags for bulk storage | Available in limited sizes such as 1kg, 5kg, 10kg, and 50kg |

| Common uses | Ideal for adding an extra protective layer for product packaging | Perfect for packaging that requires high clarity and exceptional printing quality |

Ultimately, your choice of storage bag depends on your specific business needs. PP bags offer remarkable durability and lightness, capable of carrying substantial weight. On the other hand, BOPP bags include these qualities along with the option for sharp brand printing. If you prioritize representing your brand, BOPP bags are your top choice.

If you’re looking to enhance how you store your product, reach out to K-Packing today! Our team is ready to guide you toward the best product for your requirements, whether PP bags, BOPP Bags, or FIBC bags. High-quality products deserve top-notch packaging, and we provide nothing but the best!