Environmental bags are designed to reduce plastic waste and minimize environmental impact. They help businesses promote their brand sustainably, show social responsibility, and build customer trust. For consumers, these bags are durable, reusable, and cost-saving -making everyday shopping more eco-friendly.

1. Introduction environmental bags

Environmental bags are eco-friendly packaging solutions created to replace single-use plastic and address the growing plastic pollution crisis. Developed from materials like PP non-woven, RPET, cotton, jute, and biodegradable bioplastics, they offer a more sustainable alternative while still being practical for everyday use.

For businesses, these bags are powerful branding tools – customizable, cost-effective, and perfect for events, retail, and promotional campaigns. For consumers, they are durable, reusable, and safe, helping them save money and contribute to a cleaner environment. Together, environmental bags deliver a win-win solution: better brand image for companies and a greener lifestyle for end-users.

2. Classification of environmental bags

Environmental bags can be divided into several main categories based on their materials and life cycle. This classification helps businesses and consumers choose the right solution – whether they want long-lasting reusable bags, bags made from recycled materials, or quick-to-decompose biodegradable options:

2.1 Reusable bags

Reusable bags are designed for long-term use, replacing hundreds of single-use plastic bags. They come in a wide range of materials including PP non-woven, PP woven, cotton canvas, organic cotton, recycled cotton, hemp, and jute – each with its own look and durability. Cotton and canvas bags, whether conventional, organic, or recycled, can be used over 300 times to offset production energy and can last up to 20,000 uses, making them a truly sustainable option.

Hemp bags are another eco-friendly choice, growing quickly with very little water and no need for pesticides. They also improve soil quality and are naturally resistant to mold and UV damage. Jute bags, often called the “Golden Fiber”, are the fastest-growing natural fiber bags, require minimal water, are fully biodegradable, and are highly cost-effective for bulk orders. PP non-woven and woven bags, meanwhile, are lightweight, water-resistant, customizable, and affordable – perfect for retail stores, supermarkets, and promotional campaigns.

2.2. Recycled material bags

Recycled material bags are made from post-consumer or post-industrial recycled resources, helping businesses cut plastic waste and lower carbon emissions. RPET bags are produced from recycled PET bottles, reducing CO₂ emissions by around 20% while maintaining the same strength and durability as virgin plastic. They can also be recycled again, supporting a circular economy.

PCR bags use at least 20% recycled content and are fully traceable thanks to GRS certification, which ensures compliance with strict environmental and social standards. These bags are an excellent choice for businesses that want to showcase transparency and sustainability in their supply chain.

2.3. Biodegradable bags

Biodegradable bags are made from materials designed to break down naturally, leaving little to no harmful residue. Common materials include PLA derived from corn starch, PBAT as a biodegradable polymer, 100% corn starch blends, and bagasse, a by-product of sugarcane processing.

These bags typically disintegrate within 12 weeks and fully decompose in about six months in industrial composting facilities. Under certified natural conditions, they can break down even faster – in as little as 10 to 45 days – making them a great choice for businesses looking for short-lifecycle packaging.

3. Benefits of environmental bags

Environmental bags bring value not only to businesses but also to end-users. They help companies save costs, build stronger brands, and meet global sustainability standards, while offering consumers a convenient and eco-friendly solution for daily life:

3.1 Benefits for businesses

- Save production and logistics costs: Reusable PP woven and RPET bags cut down on frequent reorders and waste management fees. Their light weight and stackable design help reduce storage and shipping costs compared to traditional packaging.

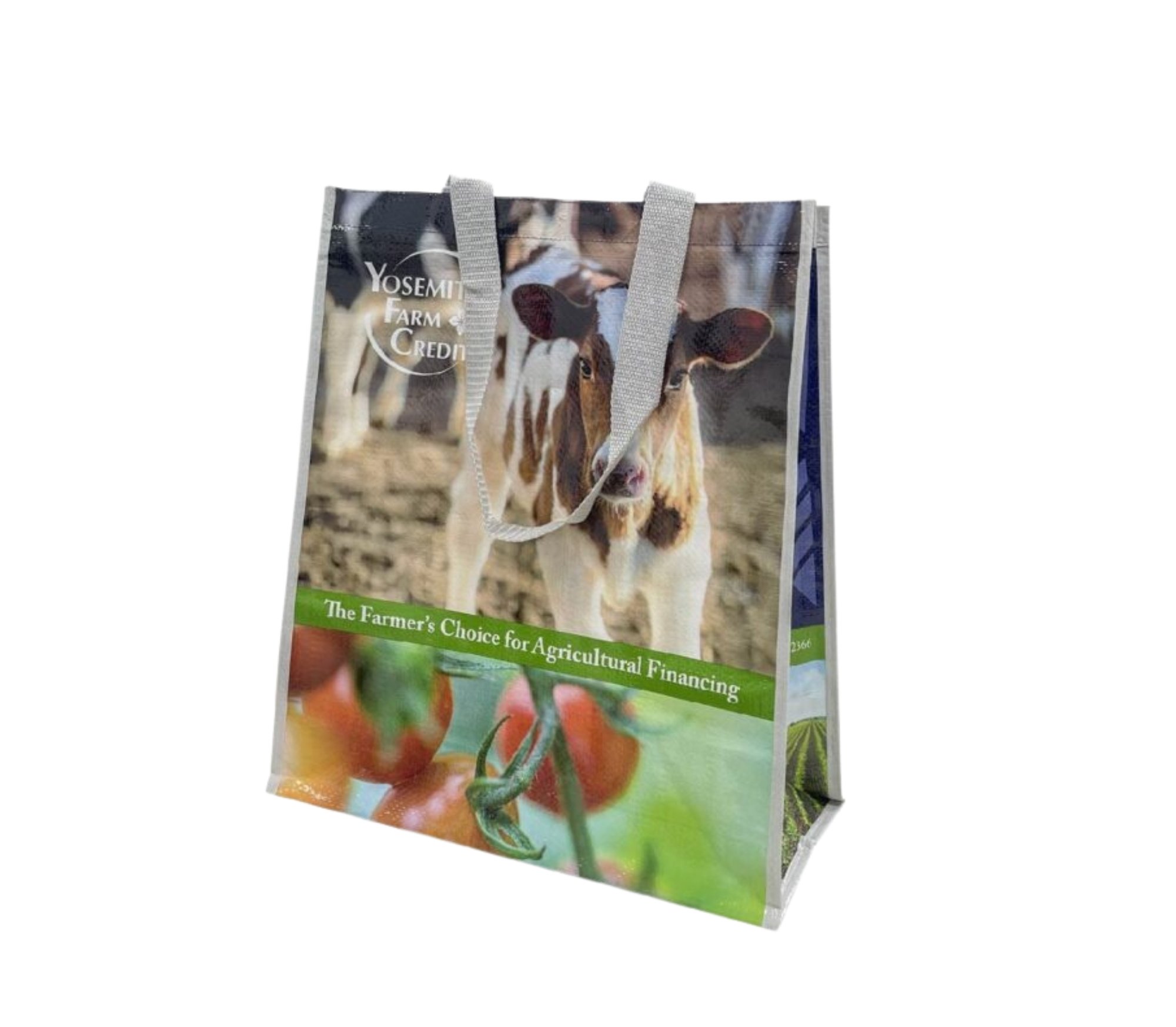

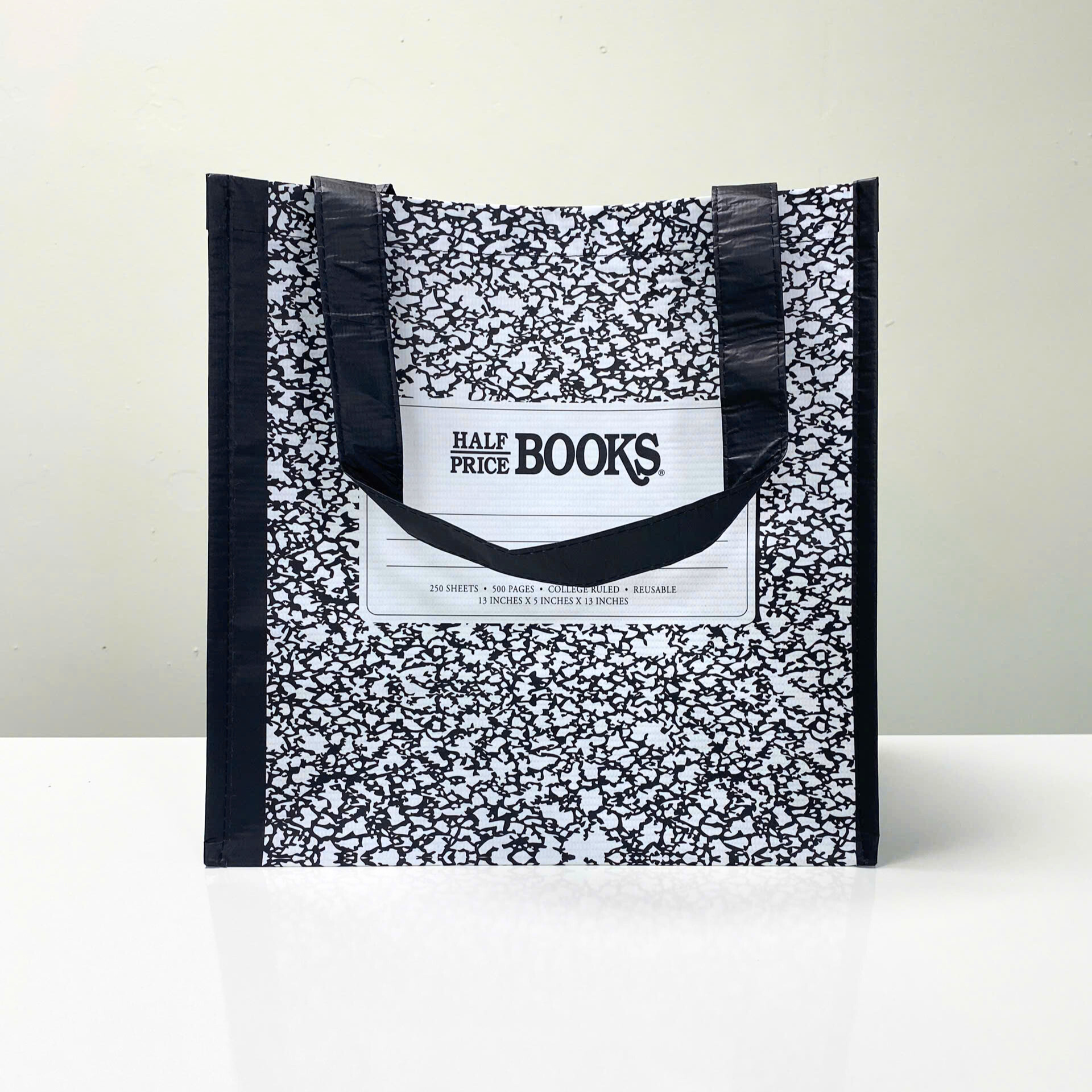

- Strengthen brand image and marketing: Each bag works like a “walking ad.” Custom-printed logos get seen every time the bag is reused, offering free brand exposure and showing your company’s commitment to sustainability.

- Stay compliant and competitive: Green packaging helps businesses meet international environmental regulations and stay ahead of future bans on single-use plastic.

- Unlock premium markets: Certified eco-bags open doors to supermarkets, export markets, and global brands that require sustainable packaging.

- Increase Revenue and Profit Margins: Eco-friendly products attract bulk orders and allow for higher pricing, boosting both sales and profit margins.

3.2 Benefits for consumers

- Safe and convenient: Made without harmful chemicals and safe for food contact, these bags are strong enough for daily shopping, school, or travel and save users money on new bags.

- Support a greener planet: Reusing bags reduces plastic waste. Compostable and biodegradable options break down naturally without harming the environment.

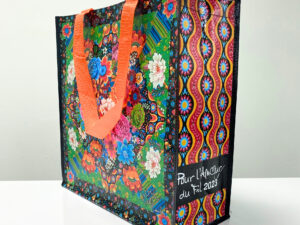

- Stylish and versatile: Available in many colors and designs, they double as gift bags or fashion accessories, letting users show off a modern, eco-conscious lifestyle.

4. Main applications of environmental bags

- Retail and supermarkets: Perfect replacement for single-use plastic bags, helping stores comply with environmental regulations and boost their green image. Reusable bags like non-woven, cotton, or RPET are durable and convenient for customers, making them ideal for everyday shopping.

- Fashion and gifting: Brands use canvas, jute, or recycled bags to package and present products. These bags add a premium touch, enhance unboxing experience, and show social responsibility – a strong message for eco-conscious shoppers.

- Hospitality and food service: Hotels, restaurants, and cafes use eco-friendly bags for laundry service, giveaways, and take-away packaging. This reduces plastic waste and creates a more sustainable, high-quality guest experience.

- Logistics and transportation: Green packaging solutions protect goods in transit while being recyclable and reducing overall plastic waste. Ideal for businesses wanting to meet sustainability goals across the supply chain.

5. Production process of environmental bags

K-Packing’s production process is designed to deliver high-quality environmental bags, from material selection to final packaging, ensuring durability, safety, and sustainability:

- Material selection & blending: We carefully choose materials such as virgin PP, recycled PET, organic cotton, jute, hemp, or biodegradable bioplastics. Additives like anti-slip, anti-fog, and eco-safe pigments are used when needed, always meeting international safety standards and client specifications.

- Extrusion & fiber production: For PP and RPET bags, raw materials are melted at controlled temperatures and formed into sheets, then cut into fibers ready for weaving or fabric formation.

- Fabric formation: Fibers are woven or non-woven into rolls of fabric. For cotton, jute, or hemp bags, high-quality natural fibers are spun and woven to create strong, uniform fabric.

- Lamination or coating: Depending on the design, the fabric may be laminated with PE or BOPP for water resistance, UV protection, or to allow vibrant, full-color printing.

- Printing & branding: Artwork is prepared digitally, then printed using gravure, screen, or digital methods. Each bag is dried and inspected to ensure sharp colors, accurate logos, and long-lasting print quality.

- Cutting, stitching & assembly: Fabrics are cut with heat-cutting machines for clean edges. Bags are stitched or heat-sealed according to specifications, with reinforced handles and seams to ensure strength for repeated use.

- Quality control & packaging: Every batch is inspected for durability, print quality, and size consistency. Bags are packed, labeled, and shipped with reliable logistics partners to guarantee fast, safe delivery.

5. Why choose K-Packing for environmental bags

K-Packing is a trusted Vietnam-based manufacturer, delivering premium environmental bags worldwide. If you only want the cheapest option, you can find plenty of Made-in-China products. But if you want sustainable, certified, and guaranteed-quality bags, K-Packing is your best choice:

- Durable & sustainable: Made from PP woven, RPET, cotton, jute, or biodegradable materials – built to last or safely decompose.

- Fully customizable: Choose size, material, color, and printing with multiple logo placement options.

- Certified quality: Produced in ISO 9001:2015 & ISO 14001:2015 facilities, meeting global export standards.

- Cost-effective & fast: Save 10–15% with factory pricing, 7–15 day production, and up to 50% off DHL shipping.

- End-to-end support: From material consultation to delivery, we make bulk ordering easy.

📧 Email: info@k-packings.com

📞 Hotline: (+84) 855 555 751

Address:

🇺🇸 USA: 7319n. Loop 1604 E, San Antonio TX 78233, United States

🇦🇴 ANGOLA: Av. Pedro de Castro Van-Dúnem Loy, Luanda, Angola

🇻🇳 VIETNAM: 169 Nguyen Ngoc Vu Street, Cau Giay District, Hanoi

Reviews

There are no reviews yet.