Pharmaceutical ingredients such as APIs, excipients, and powdered blends are extremely sensitive to moisture, contamination, and improper handling. Even minor exposure can reduce potency, compromise sterility, and put patient safety at risk. This makes choosing the right bulk packaging solution critical for the entire pharmaceutical supply chain.

FIBC bags provide a trusted answer to these challenges. With pharma-grade certification, protective liners, and compliance with FDA and EU GMP standards, they keep products pure, stable, and traceable. For businesses, this means fewer losses, safer logistics, and stronger customer confidence. In the following sections, we will explore how FIBC bags protect pharmaceutical products at every stage.

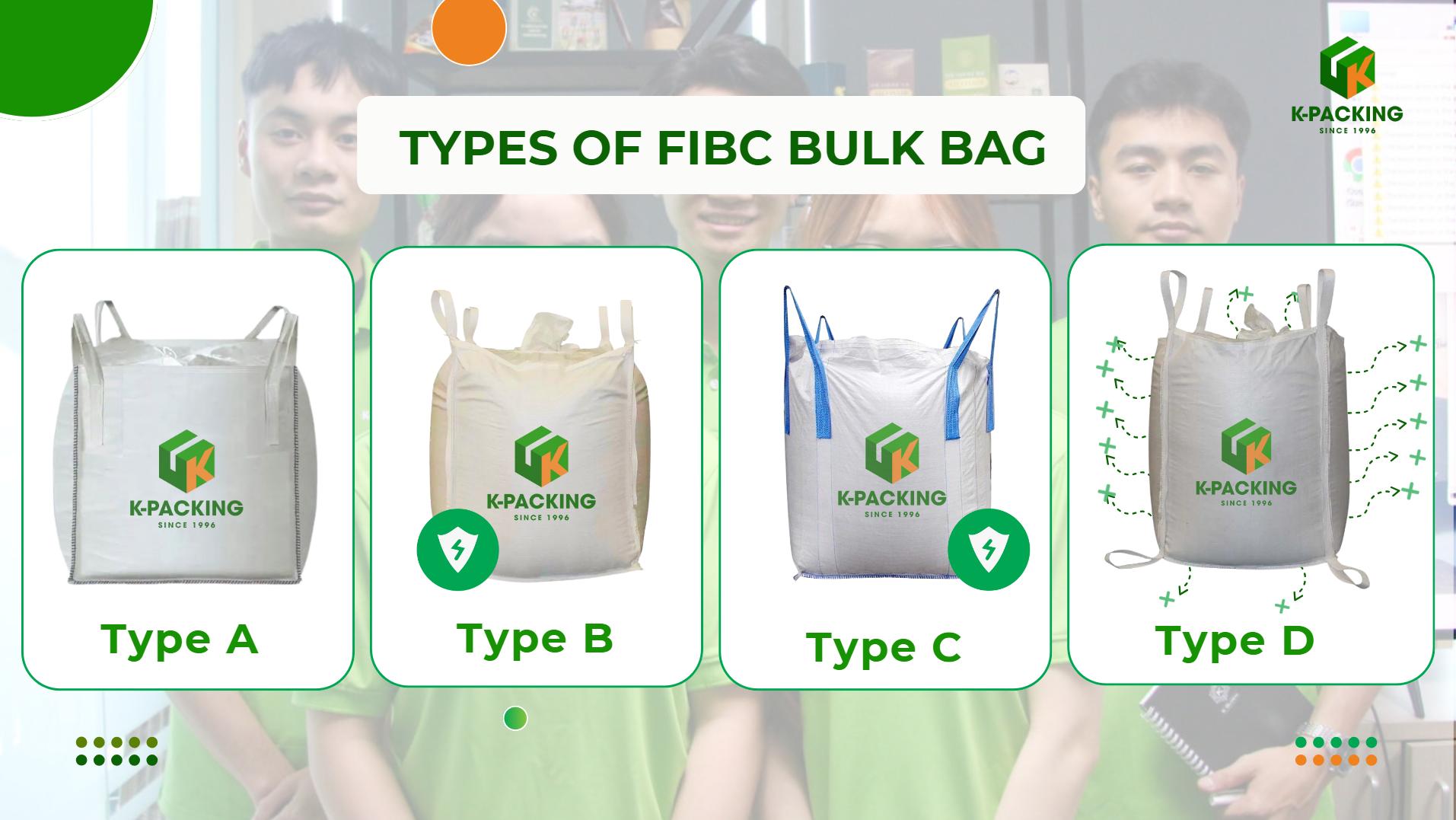

1. Choosing the right FIBC bags

Pharmaceutical products such as APIs (Active Pharmaceutical Ingredients), excipients like lactose or starch, and powdered blends are extremely sensitive to contamination, moisture, and improper handling. Standard industrial packaging is not acceptable because even a small impurity can compromise product safety.

The correct choice is pharma-grade or food-grade FIBC bags, manufactured in controlled clean-room environments. These bags comply with FDA and EU GMP standards, which ensures they are safe for contact with pharmaceutical ingredients. For bulk handling, companies should only select FIBCs that meet the safety factor ratio of 5:1 (single-use) or 6:1 (multi-use/reusable), guaranteeing that each bag can withstand five to six times its intended load without failure.

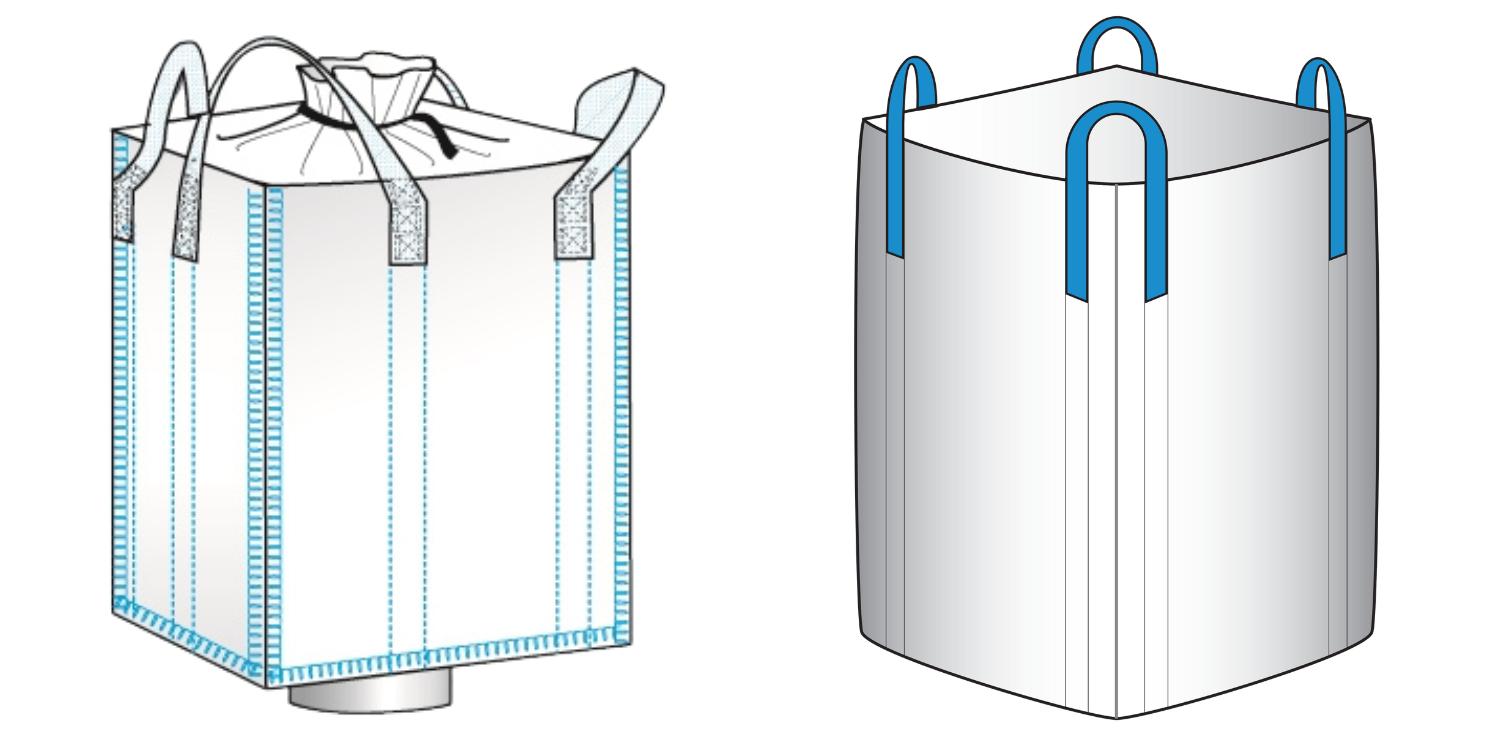

For moisture-sensitive APIs or hygroscopic excipients, liners are mandatory. PE, EVOH, or aluminum liners block oxygen and humidity, extending shelf life and preventing degradation. Without a liner, APIs may oxidize or lose potency during storage and transit.

2. Preparing pharmaceuticals before packing

Pharmaceutical powders must be carefully conditioned before filling into FIBCs. APIs are dried to precise moisture levels, usually below 5%, to prevent microbial growth or chemical reactions. Excipients such as lactose or starch are sieved and sterilized to meet GMP requirements.

The packing area must follow Good Manufacturing Practice (GMP): filtered air, strict hygiene for operators, and sanitized equipment. Cross-contamination between different products is not allowed, so equipment should be cleaned and validated before each use.

If liners are used, they are pre-inflated inside the FIBC before filling. This ensures the liner fits smoothly against the bag wall without folds or creases, which could trap powder and cause uneven filling. For highly oxygen-sensitive products, nitrogen flushing inside the liner reduces oxidation risk and preserves product stability.

3. Packing process

Pharmaceuticals are filled into FIBCs using a closed-loop filling system. This prevents dust release into the environment and maintains product sterility. APIs, in particular, are expensive and hazardous in fine dust form, so closed systems protect both product yield and worker safety.

After filling, the liner must be sealed. Heat sealing is preferred, as it creates an airtight and tamper-evident closure. Tying with cable ties may be acceptable for short-term storage, but it cannot guarantee long-term protection. The outer FIBC spout is then secured by stitching or sealing to prevent leakage or dust escape.

Each FIBC must carry detailed labeling: product name, batch number, manufacturing date, expiry date, and storage conditions. This labeling is not just for logistics – it is a regulatory requirement. Pharmaceutical shipments must be fully traceable for recalls, audits, or quality inspections.

4. Storage and handling

Pharmaceutical FIBCs must be stored in temperature-controlled warehouses. Most APIs require 15–25°C and low humidity levels, while some sensitive excipients may require refrigeration. FIBCs must be stacked on pallets, never placed directly on the floor, and should not touch walls to avoid moisture transfer.

Warehouses should have air filtration systems to keep dust and microbes out. Operators must wear protective clothing and follow hygiene protocols when handling bags. For long-term storage, desiccants can be placed inside the liner to stabilize humidity.

During handling, forklifts or cranes should use the lifting loops provided. Bags must never be dragged or pierced, as this can tear the fabric and allow contamination. For APIs and high-value products, secondary protective covers may be used to provide an additional barrier during storage.

5. Transportation

Pharmaceuticals require clean, sanitized, and sealed containers for transport. Containers must be dry, odor-free, and protected against direct sunlight. Since APIs and excipients are highly hygroscopic, desiccants and container linings are strongly recommended, especially for sea freight where “container rain” can occur due to temperature fluctuations.

Moisture is the most common cause of product damage during long journeys. Even small exposure can cause APIs to lose potency or excipients to clump, making them unsuitable for use in formulations. Using liners and moisture protection ensures that products arrive in stable condition.

Documentation is also critical. Each shipment must include Certificates of Analysis (CoA), GMP compliance records, and batch details. Without these documents, pharmaceutical cargo can be delayed, rejected, or even destroyed at customs.

Conclusion

FIBC bags provide a safe and efficient bulk packaging solution for pharmaceuticals, ensuring purity, stability, and compliance. With pharma-grade certification, protective liners, and adherence to safety factors of 5:1 or 6:1, they safeguard sensitive ingredients throughout storage and transportation.

For businesses, this means lower risks of contamination, longer product shelf life, and full compliance with FDA and EU GMP regulations. Most importantly, it protects the company’s reputation in a highly regulated global market. By adopting FIBCs correctly, enterprises can deliver pharmaceuticals safely, maintain customer trust, and compete more effectively worldwide.