In industries such as food, chemicals, and construction, issues like moisture damage, product caking, and material loss often result in significant costs and compromised product quality. Standard packaging cannot provide complete moisture protection or prevent dust and humidity from affecting sensitive products, creating risks during storage and transportation.

As a leading manufacturer and wholesale exporter of PP woven bags from Vietnam, we offer PP Woven Bags with Liner — a premium packaging solution featuring a PE liner for absolute moisture protection, superior strength, and product safety. This solution helps businesses preserve product quality, minimize losses, reduce long-term costs, and strengthen their brand reputation by meeting international quality standards.

1. Product Parameters

| Name | PP woven bag with liner |

| Materials | 100% PP granules |

| Size | From 30-220 cm, As per customer’s requirements |

| Width | As per requirement |

| Fabric | 50, 55, 60, 65, 70 up to 220 GSM or even higher as per requirement. |

| Density | 4.5 x 4.5 and up to 15 x 15 |

| Top | Heat cut/zig-zag/stitch/Welding |

| Bottom | Single fold/stitch, single fold/double stitch, double fold/stitch |

| Loading | 5kg, 20kg, 25kg, 50kg, 100kg |

| Colour | White or as per requirement |

| Printing | As per requirement |

| MOQ | 1.000 |

| Certificate | ISO, SGS, UN |

| Package | 100pcs/bundle, 1000pcs/bale, or as customers’ requirements |

2. Choose the Right Liner: Key Features, Uses & Drawbacks

Understand the key differences between HDPE, LDPE, and LLDPE liners so you can choose the best option for your packaging needs. This comparison highlights their features, ideal applications, and possible drawbacks, helping you make a confident decision.

| Liner Type | Key Features | Best For | Drawbacks |

|---|---|---|---|

| HDPE (High Density PE) | Thin, rigid, excellent moisture barrier | Injection molding, flat yarn, products needing a stiff form | Less flexible, can crack under repeated folding |

| LDPE (Low Density PE) | Soft, transparent, very flexible | Sugar bags, fertilizer, garbage bags | Lower strength, easier to tear under heavy load |

| LLDPE (Linear Low Density PE) | Superior puncture and tear resistance | Industrial bags, ice bags, heavy-duty packaging | Slightly more expensive, less transparent |

Choosing the right liner depends on your product’s sensitivity and packaging goals.

- If you need maximum moisture protection and a stiff, form-holding bag, HDPE liners are the best choice.

- For cost-effective, flexible, and transparent packaging, go with LDPE liners — ideal for sugar, fertilizer, and other dry goods.

- When you require superior strength and puncture resistance for heavy-duty applications, choose LLDPE liners for long-lasting performance.

No matter which option you choose, our PP Woven Bags with Liner are designed to protect your goods, streamline packing, and meet strict export requirements — helping your business save costs and deliver products safely to customers.

See more in our PP Woven Bags collection

3. Why Choose K-Packing PP Woven Bags with Liner?

K-Packing is proud to be one of Vietnam’s leading manufacturers and wholesalers specializing in PP woven bags with PE liner — the premium solution for moisture-sensitive products such as rice, sugar, flour, fertilizers, and chemicals. With over 27 years of industry experience (established in 1996), our factory is certified with ISO 9001:2015 and ISO 14001:2015, meeting international quality standards and exporting to over 30 countries worldwide.

Our product range includes lined PP woven bags, laminated bags, and fully customized packaging solutions. Using advanced production lines and competitive labor costs, we deliver high-quality, cost-effective, and food-safe packaging that fully complies with your export requirements.

3.1. Benefits of Choosing Our Lined PP Woven Bags

- Customizable Design: Select the exact liner type (HDPE, LDPE, or LLDPE), bag size, GSM, color, and printing to match your product requirements.

- Superior Protection: PE liner ensures moisture-proof, leak-proof packaging — ideal for sensitive goods.

- Consistent Quality: Produced on modern looms, cutting and sewing machines, and high-precision printing lines for uniform results.

- Best Market Price: 10–15% lower than competitors thanks to direct manufacturing — no middleman markup.

- Hassle-Free Ordering: Streamlined process for fast quotations, accurate production, and on-time delivery.

3.2. Our Commitments to Customers

- Competitive Bulk Pricing: Clear tiered pricing and attractive discounts for large orders (typically 5–10%).

- Reliable Delivery: Fast lead times from 3–15 days, with compensation or priority re-shipment for any delays.

- Strict Quality Control: Every bag is thoroughly inspected; defective items are replaced or refunded under our 20% return policy.

- Flexible Customization: Logo printing, lamination, and PE liner sewing options to meet your branding and technical needs.

- Dedicated Customer Support: Our team is available before, during, and after purchase to ensure a smooth experience.

Below are some pictures of our PP Woven Bags With Liner:

You can customise the product parameters according to your requirements and create your own PP woven bags with liner

The process of making a PP Woven Bags with liner goes like this:

3.3. Packaging & shipping

We ensure that every order of PP Woven Bags with Liner is shipped quickly and safely through our network of trusted logistics partners — including J&T Express, DHL, FedEx, UPS, Yusen Logistics, and Hapag-Lloyd.

Choosing UPS gives you up to 50% savings on shipping fees and faster delivery times, thanks to our high-volume authorized agent status — so your lined PP woven bags arrive on time and ready for production or resale.

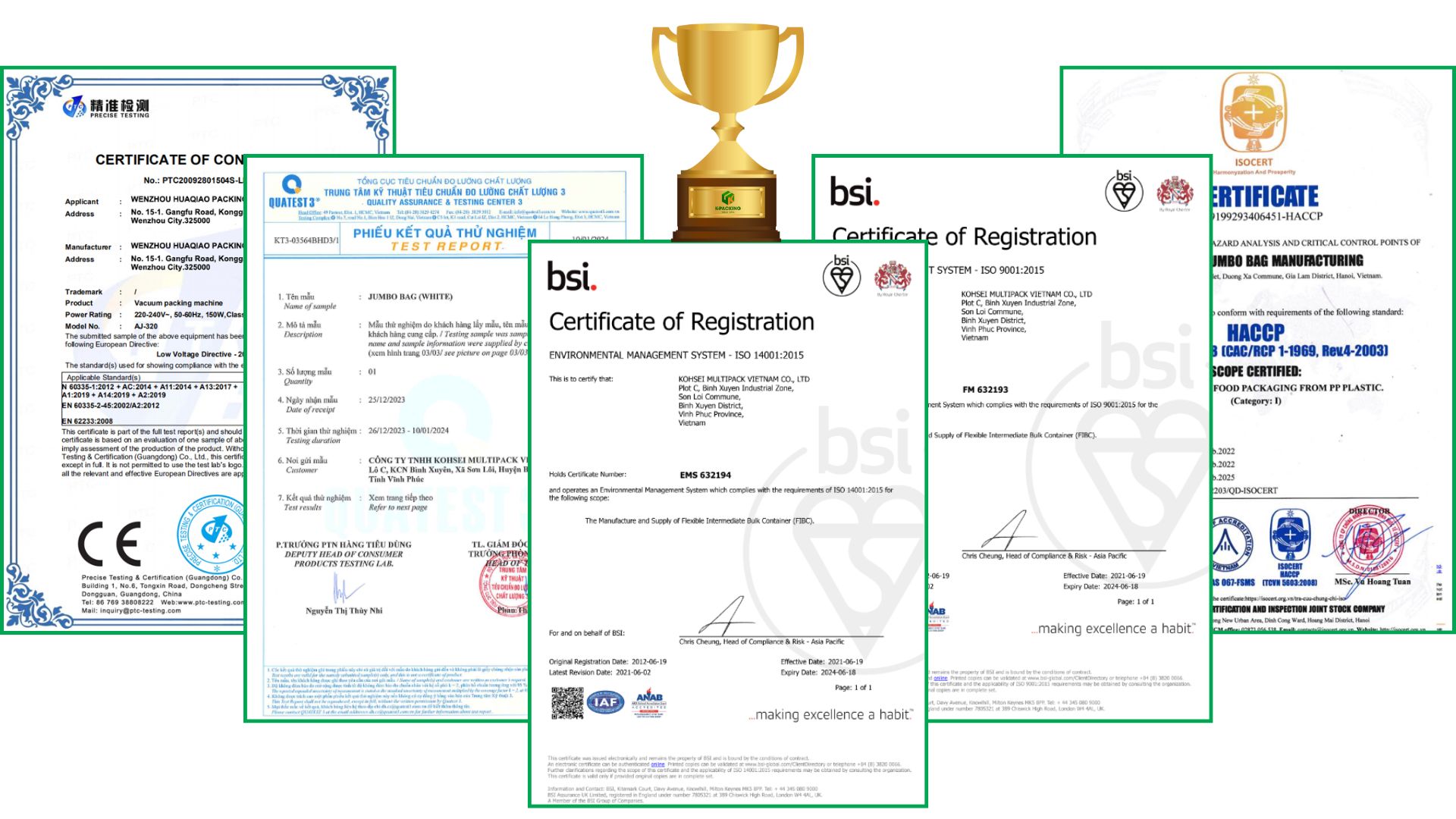

Certifications

Our PP Woven Bags With Liner all have full ISO certification (ISO 9001:2015; ISO 14001:2015), Certificate ensuring the performance of loose soil containers in terms of weather resistance (products used to store chemicals that emit nuclear radiation emissions in Japan)…

FAQs

Yes, we can customise the design based on your artwork or requirements. Yes, samples are available. Stock samples are free, but you must cover the courier charges. Typically, sample delivery takes 5-8 working days. We are a manufacturer specialising in packaging for over 10 years. Our advanced equipment ensures high quality and competitive prices! So, you can rest assured about the quality of our PP Woven Bags With Liner. We offer flexible payment options, typically requiring a minimum 50% deposit upon order placement and the remaining 50% before shipment. For larger orders (FIBC > 1000, PP > 50,000), a 35% deposit is required, with the rest payable upon shipment. We accept various payment methods, including bank transfers, letters of credit, and online payment gateways. Our sales team will guide you through the payment process and provide detailed conditions tailored to your order. Contact us with your requirements (size, colour, material, printing, specifications, etc.), via WhatsApp, Email or our Sales.

Reviews

There are no reviews yet.