1. What is a PP Woven Bag?

A PP woven bag is a type of flexible packaging made from polypropylene (PP) – a thermoplastic polymer that is extruded into tapes and woven into a strong fabric. These polypropylene tapes are interwoven in a criss-cross pattern, forming a tightly bonded structure that delivers excellent tensile strength, load-bearing capacity, and long service life.

PP woven bags are known for their versatility, cost-effectiveness, and reliability, and are widely used across industries such as agriculture, food processing, chemicals, construction, and retail. They are an ideal solution for storing and transporting a variety of goods, including rice, fertilizer, cement, animal feed, and grains.

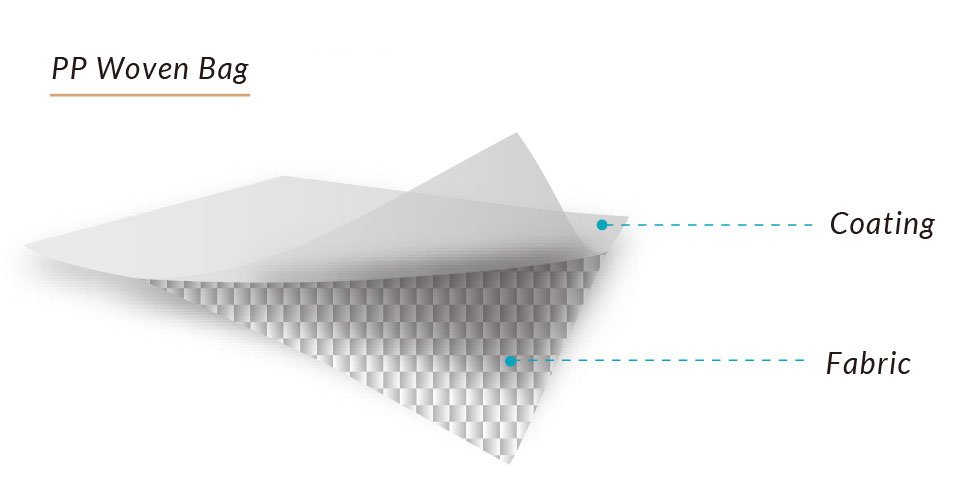

2. PP Woven Bag Structure

A PP woven bag is like a strong, reusable sack made from plastic strips woven together – it looks like fabric but is much stronger.

- Outer Fabric: The main layer, made from woven polypropylene strips. This is what makes the bag strong and able to carry heavy loads.

- Protective Coating (Optional): A thin layer on the outside or inside that makes the bag water-resistant and keeps the contents dry.

- Inner Liner (Optional): A thin plastic bag inside for products that must stay completely clean and dry, such as rice, sugar, or fine powders.

- Top & Bottom: The top can be heat-cut or neatly sewn. The bottom is folded and stitched tightly to keep the contents secure.

3. PP Woven Bag Production Process – Made in Vietnam

K-Packing has been in operation since 1996, specializing in serving the agriculture industry and Japanese-invested enterprises in Vietnam. Today, we operate five factories across Vietnam, ensuring large-scale production capacity and consistent supply.

Our facilities follow LEAN manufacturing standards, focusing on eliminating waste, improving efficiency, and maximizing value for customers. Combined with our state-of-the-art machinery, this approach allows us to streamline every step of production, reduce unnecessary costs, shorten lead times, and maintain consistently high product quality.

8-Step Manufacturing of Export-Grade Bags

- Processing Raw Material: Virgin PP resin is carefully selected to meet ISO standards and food safety requirements.

- Extruding: The resin is melted, extruded, and stretched into flat tapes, increasing tensile strength and preparing them for weaving.

- Weaving Fabric: The tapes are woven on modern circular looms to produce strong, uniform fabric with minimal defects.

- Laminating: A layer of PE or BOPP film is applied for moisture and dust resistance, and to allow high-quality printing.

- Cutting: The woven fabric is cut precisely to size using automated cutting machines, ensuring consistency.

- Sealing & Stitching: The bag top and bottom are heat-sealed or double-stitched for extra strength and safe handling.

- Quality Control & Warehousing: Each bag is tested for strength, dimensions, and durability before being packed for shipment.

- Packaging & Shipping: Bags are packed securely and prepared for export, reaching customers in over 30 countries worldwide.

4. Top 5 Most Popular PP Woven Bags

Based on current market demand and industry usage, here are the five most widely used types of PP woven bags across food, agriculture, and industrial sectors.

1. PP Woven Rice & Sugar Bags

These are the most common PP woven bags used in the food industry. Available in 5kg, 10kg, 25kg, and 50kg sizes, they are suitable for both retail and bulk export. Their breathable woven structure helps keep rice dry and fresh while preventing mold. These bags are the go-to solution for packing rice, refined sugar, and various agricultural products, accounting for around 45% of the food packaging market share.

2. PP Woven Fertilizer Bags

Specially designed for agricultural use, these bags resist acids and alkalis commonly found in fertilizers. They have a loading capacity of 25–50kg, with single or double-stitched bottoms for extra strength. Their moisture resistance prevents caking, maintaining fertilizer quality during storage and transport. Fertilizer bags make up roughly 35% of the agricultural packaging market.

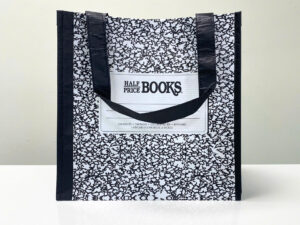

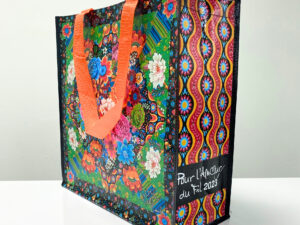

3. PP Woven Shopping Bags

Durable, reusable, and eco-friendly, these bags are popular for retail and promotional purposes. They can be flexo-printed with brand logos and come in brown or white kraft-look finishes, making them an excellent alternative to single-use plastic bags.

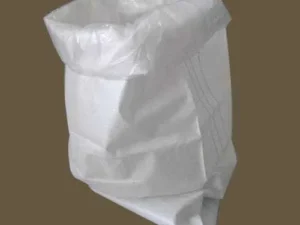

4. PP Woven Bags with Liner

These bags offer dual protection: a strong woven PP outer layer and a PE inner liner that provides complete moisture protection. They are commonly used for chemicals, cement, fine powders, and any product that requires strict preservation standards. Their near 99.9% leak-proof reliability makes them a safe choice for sensitive applications.

5. PP Woven Animal Feed Bags

Animal feed bags are essential in the livestock and aquaculture industries. Designed to hold 25–50kg, they protect feed from moisture and contamination, preserving its nutritional value. These bags also support custom printing for branding, product information, and usage instructions, helping feed producers maintain a professional market presence. Demand continues to grow alongside the global livestock and poultry sectors.

Market Insights

According to DataHorizzon Research, the global PP woven bag market is projected to grow at a CAGR of around 5.8% between 2023 and 2032. Growth is driven by increasing demand for sustainable, reusable, and food-safe packaging solutions. The Asia–Pacific region is expected to remain the leading consumer market due to its rapidly expanding agriculture, animal feed, and food export industries.

This confirms that PP woven bags will continue to be the preferred choice for businesses looking to protect product quality, optimize logistics costs, and enhance brand presence worldwide.

5. Why Choose K-Packing PP Woven Bags?

K-Packing is one of Vietnam’s leading manufacturers and wholesalers of PP woven bags. Established in 1996, we have over 27 years of experience, operate five factories, and export to more than 30 countries worldwide. All facilities are ISO 9001:2015 and ISO 14001:2015 certified, meeting strict Japanese quality standards.

We produce PP woven bags in custom sizes, colors, GSM (from 65 GSM), and printing options to fit your needs. Our high-capacity looms, precision sewing machines, and multi-color printing systems ensure consistent quality. As a direct manufacturer, we offer prices 10–15% lower than most competitors, while keeping products safe, food-grade, and export-ready.

Our standard lead time is 3–15 days depending on destination, and if a shipment is delayed we prioritize re-shipment or provide fair compensation. Each bag is strictly inspected, and defective products are replaced or refunded under our 20% return policy.

We work with trusted carriers such as DHL, FedEx, UPS, and Yusen Logistics to ensure safe, fast delivery. Choosing UPS gives you up to 50% lower shipping costs and faster handling thanks to our status as a high-volume authorized agent.

All products carry full ISO certifications, ensuring strength, safety, and environmental compliance for international markets.