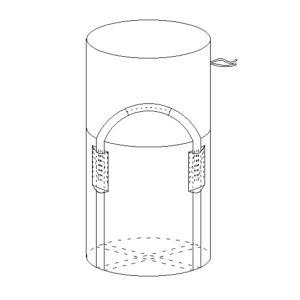

UN Flexible Bulk Containers Bag is a bulk bag, specifically designed to contain dangerous goods that cannot be contained in conventional FIBC bags. UN FIBC bags are specifically designed to meet the requirements set by the United Nations (UN) for the transport and storage of hazardous materials. These bags are produced, examined, and certified for use with a variety of products in conditions where there is the risk of explosion, fire, chemical burns, poisoning, or harm to the environment. These types of goods often include:

- Chemicals: Substances that are corrosive, toxic, or flammable

- Hazardous waste: Industrial or medical waste that has the potential to pollute the environment

- Materials Flammable: Products capable of causing fire or explosion

- Toxic substances: Substances that may be hazardous to human or animal health

UN Certified Bulk Bags is:

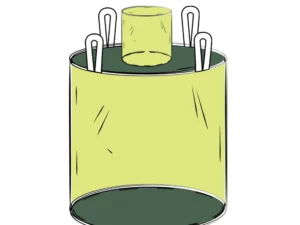

- Made from durable polypropylene or polyethylene textile material, resistant to leaks, spills, and contamination from internal or external factors.

- Designed with higher durability and bearing capacity than conventional FIBC bags.

- Available in a variety of sizes and capacities to accommodate a wide range of dangerous goods.

- Equipped with an inner lining to prevent leaks and protect the product.

- Can be reused many times, contributing to environmental protection.

Benefits of using UN jumbo bags:

- Ensure safety when transporting and storing dangerous goods.

- Minimize risks associated with the management and transportation of dangerous goods.

- Protect the environment and people from risks such as fire, explosion, toxicity, and chemical pollution.

- Suitable for transporting dangerous goods via means such as road, air, and sea

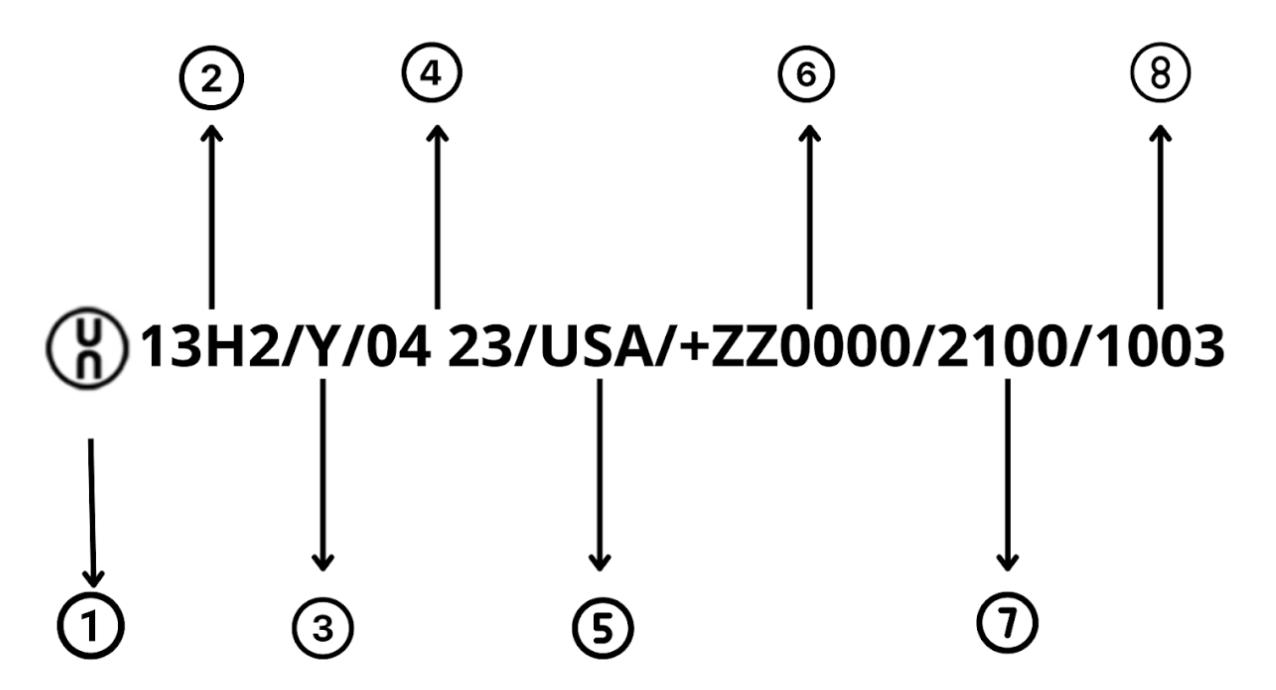

UN FIBC bags labeling & identification

UN bags are specifically designed to store and transport hazardous materials, therefore to use bags safely, the United Nations has established specific criteria for identifying bags and their contents. These criteria allow users to track the origin, materials, manufacturer, coating and other important factors of each bag. The picture below will specifically illustrate the identification and labeling standards of UN Certified Bulk Bags.

- United Nations Packaging Logo

- Code number designating FIBC design type

- Capital letter identifying the performance standard under which the design type has been successfully tested

- The numerical month and year of manufacture

- Country authorizing allocation of the mark

- The name and address or symbol of the manufacturer or the approval agency certifying compliance with subpart N and subpart O of 178

- The stacking test load in kilograms

- Maximum gross mass

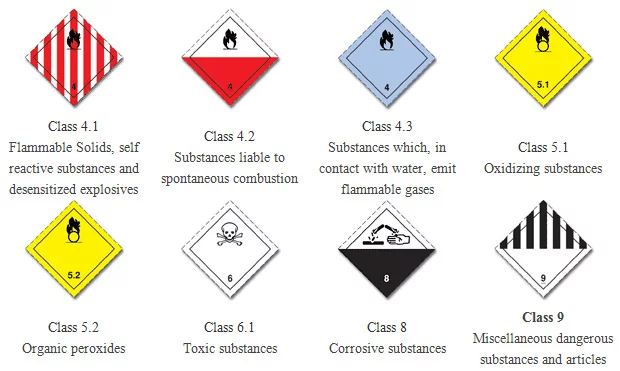

Categories of UN Approved Bags

Dangerous products are classified by the United Nations according to a unique UN product number, which must be attached to your UN approved bag. These product codes and the corresponding packaging group classifications below can also be found in the “orange book”.

Classes of UN rated bags

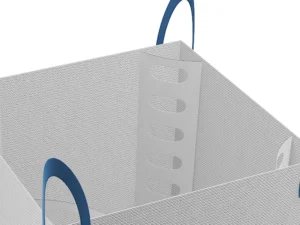

To be considered a UN-certified FIBC, Un FIBC bags need to be clearly labeled with the hazardous materials they contain. They are divided into 8 types as depicted in the image below:

Why choose K-Packing to supply your UN certified bags?

1. We rigorously test our UN rated FIBC bags

Each UN Bulk Bags, manufactured by K-Packing, must be tested according to the following United Nations standards:

- Top Lift Test: The FIBC bag is filled with material to its Safe Working Load (SWL) and then hung up using the lifting straps. UN Certified from K-Packing meets UN standards including: the bag maintains a load equal to six times its safe working load (6:01) for five minutes.

- Vibration Testing: To test the vibration of a UN certified FIBC bag, the bag is placed on a vibrating platform and subjected to a 60-minute vibration test. After 60 minutes, K-Packing’s UN bags are not torn and there is no leakage of goods.

- Stack Testing: 2 UN FIBC bags are filled to the SWL (6:01) and placed stacked on top of each other. The bag below can withstand 24 hours without damage to the bag and the goods inside.

- Drop testing: The bags are filled with material and dropped from 3 specific heights according to the packaging group. During this process, the UN certified bag does not lose its contents.

- Topple Testing: Bags are tipped from a specific height based on the packing group. As a result, no product falls out.

- Tear Testing: The bag is punctured with a knife at a 45° angle. Part 1 of the test is a uniform top load to the maximum allowable safe working load. The bag must be left in place for at least 5 minutes. Part two of the test requires the bag to maintain its integrity through a 45° cut when suspended for 5 minutes. The cut should not extend more than 25% of its original length.

- Righting Testing: The bag is lifted to a vertical position from its side. The condition is that the bag is not damaged or torn.

Because of our strict testing process, K-Packing’s UN FIBC bags were used in the radioactive water leak at the Fukushima nuclear power plant in Japan in 2011. We are always proud to be The Japanese government’s trust and long-term cooperation include the use of FIBC bags to contain sand and rocks to prevent floods and overcome the consequences of natural disasters.

2. Our UN rated bulk bags follow The Orange Book Guidelines

The United Nations has issued a set of guidelines for FIBC Bulk Bags of Dangerous Goods that are known as the “Orange Book,” with the goal of preventing property damage, environmental harm, and human injury.

UN-rated bulk bags are classified into six types in the book: fiberboard, metal, composite, flexible, stiff, and composite.

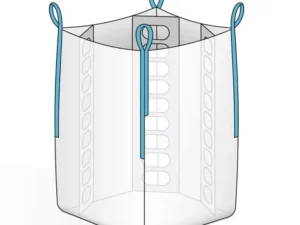

Here are 4 types of bulk bags that are commonly used around the world:

- 13H1 – Woven PP fabric without coating or without inner liner

- 13H2 – Woven PP fabric, coated

- 13H3 – Woven PP fabric with inner liner, without coating

- 13H4 – Woven PP fabric, coated and with inner liner

3. FIBC Bulk Bags for sale with the lowest price

K-Packing is proud to be the leading FIBC packaging manufacturer in Vietnam. We have more than 20 years of experience in this field with a large number of loyal customers from the US, Canada, UK, Malaysia, Singapore, Africa,…. Customers always trust and choose us because K-Packing always brings them the lowest cost for FIBC Bags. The FIBC packaging production process at K-Packing complies with Japanese standards. In short, the most special thing K-Packing brings to customers is high quality products at the cheapest prices on the market.

FAQs

The Safe Working Load (SWL) refers to the carrying capacity or ultimate state of the bag against uncontrolled external impacts during use.

The 5:01 SWL is the standard size for a single trip and has a cycle consisting of packaging, storage, transportation, and unloading from the packaging. When the standard is reached, the carrying capacity of the bag is 5 times the design load. When the impact force must exceed 5 times the working load in the last cycle, that is, when it exceeds 5000 kg,

The 6:01 SWL is a requirement for reusable giant bags. Including multiple usage cycles of loading, storage, transportation, and unloading, until there is a platform mark, tearing. When the force applied to the bag in the last cycle must exceed 6 times the working load of the bag, the safety factor is 6:1, which exceeds 6000 kilograms.

UN certified FIBC bags are generally designed for single use, especially when containing dangerous goods. However, UN FIBC bags can be reused many times under specific conditions because of its safety factor of 6:01. If they are reused, they must be thoroughly inspected after each use. To ensure safety, you can consult the manufacturer.

Experts from K-packing are always willing to help and answer all your questions.

Yes, of course. UN certified FIBC bags have higher SWL and standards compared to standard FIBC bags because they are used to contain special goods. Therefore, the price of UN Certified FIBC bags is often higher than FIBC Type A, B, C, D bags.

In Vietnam, there are many suppliers of UN Certified bulk bags including K-Packing, EPP, Thuan Duc Corporation,… Among those suppliers, K-Packing has a huge advantage when cooperating with partners. KMV – a company specializing in manufacturing FIBC packaging in Japan. Therefore, K-Packing inherits Japanese technology and production lines. K-Packing is proud to be the leading manufacturer in Vietnam of UN FIBC bags. For more information, please contact us via website: https://k-packings.com/

Reviews

There are no reviews yet.