Recycled plastic bags are bags made from used plastic that has been collected and processed to create new products, helping reduce plastic waste and protect the environment.

1. Introduction recycled plastic bags

Recycled plastic bags are made from post-consumer plastic such as bottles, packaging, and film. These materials are collected, cleaned, shredded, and recycled into new plastic pellets, which are then used to produce durable, reusable bags. This is one of the most popular eco-friendly packaging solutions today, helping reduce plastic waste and minimize environmental impact.

This product was created in response to the urgent need to cut plastic pollution and promote sustainable development. For businesses, recycled plastic bags help build a green brand image, meet ESG standards, and lower material costs by using recycled inputs. For consumers, they offer a safe, sturdy, and sustainable choice while supporting a circular economy and protecting the planet.

2. Common types of recycled plastics bags

Recycled plastic bags are made from used plastics that are collected and turned into new materials. Here are the main types of recycled plastics and how they are used in packaging:

1. PP (Polypropylene)

PP is one of the most widely used plastics in the packaging industry, especially for industrial packaging and woven bags.

It has excellent heat resistance, does not deform under high temperatures, and offers high mechanical strength. This makes PP the ideal choice for packaging products such as rice, sugar, fertilizer, or other heavy-duty woven bags.

Although its initial production cost is higher compared to some other plastics, PP has the advantage of being reusable many times, helping businesses save costs in the long run and reduce waste generation.

The recycling process of PP includes collecting → sorting → cleaning → shredding → reprocessing into new plastic pellets, which are then used to produce new high-quality products. This is both an economical and environmentally friendly solution.

2. PET (Polyethylene Terephthalate)

PET is a familiar type of plastic commonly used for producing beverage bottles, food packaging, and clear plastic bags.

It is well-known for its high transparency, glossy surface, and excellent barrier properties that help preserve food effectively. PET is also lightweight, strong, easy to transport, and very easy to recycle.

PET is the most widely recycled plastic in the world. Recycled PET can be spun into polyester fibers for the textile industry or used again to produce food-grade packaging, reducing the demand for virgin plastic.

3. HDPE (High-Density Polyethylene)

HDPE is commonly used to make shopping bags, garbage bags, chemical bottles, and industrial packaging.

Its key advantages are strength, chemical resistance, and good load-bearing capacity. Recycled HDPE (rHDPE) is typically priced around USD 1,000–1,200 per ton, making it suitable for mass production.

However, HDPE has the disadvantage of being less flexible and may crack when exposed to prolonged cold temperatures or heavy bending.

4. LDPE (Low-Density Polyethylene)

LDPE is a soft and flexible plastic often used for producing thin plastic bags and food wraps.

Its main drawback is that it is harder to recycle because it is easily contaminated, which makes processing more expensive and results in a lower recycling rate compared to PET or PP.

3. Benefits of recycled plastic bags

Recycled plastic bags bring benefits not only to businesses but also to consumers. For businesses, they improve brand reputation, lower costs, and open new markets. For consumers, they offer a practical and eco-friendly choice. Below are the key benefits divided by audience:

3.1. Business benefits

- Brand Iimage improvement: Using recycled plastic bags helps businesses build a “green” and responsible brand image. This creates trust, attracts eco-conscious customers, and strengthens competitive advantage—especially in global markets where sustainability is prioritized.

- Regulatory compliance & risk reduction: Many developed countries have strict environmental regulations. By using recycled packaging, businesses avoid fines, export bans, or trade barriers related to non-compliance.

- Lower production costs: Recycled plastic is generally cheaper than virgin plastic, which reduces raw material costs and minimizes dependency on finite natural resources.

- Market expansion & global partnerships: International retailers and distributors increasingly prefer recycled packaging. This opens more opportunities for export and collaboration, particularly in the EU and US markets.

- Access to certifications & green finance: Producing bags that meet standards such as GRS or RCS allows businesses to join support programs, receive tax incentives, and access investment funds for sustainable development.

2. Consumer benefits

- Environmental protection: Choosing recycled bags reduces plastic waste, keeps communities cleaner, and directly improves public health and quality of life.

- Easy identification of green products: Labels like “Recycled” make it simple for shoppers to choose sustainable products and express their commitment to eco-friendly living.

- Long-term cost savings: Recycled plastic bags are more durable and reusable, helping consumers save money by buying fewer single-use bags.

- Positive social impact: Using recycled products encourages others to adopt green habits, raising awareness and supporting collective action for the environment.

4.Applications of recycled plastic bags

Recycled plastic bags are not just an idea – they are already used in many industries and everyday life. From commercial packaging to agriculture, these applications show how recycled PP and rPET can reduce waste, cut costs, and support a circular economy:

4.1. Commercial packaging

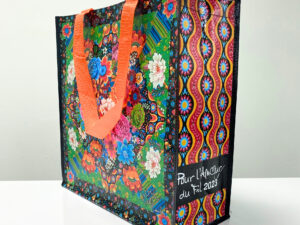

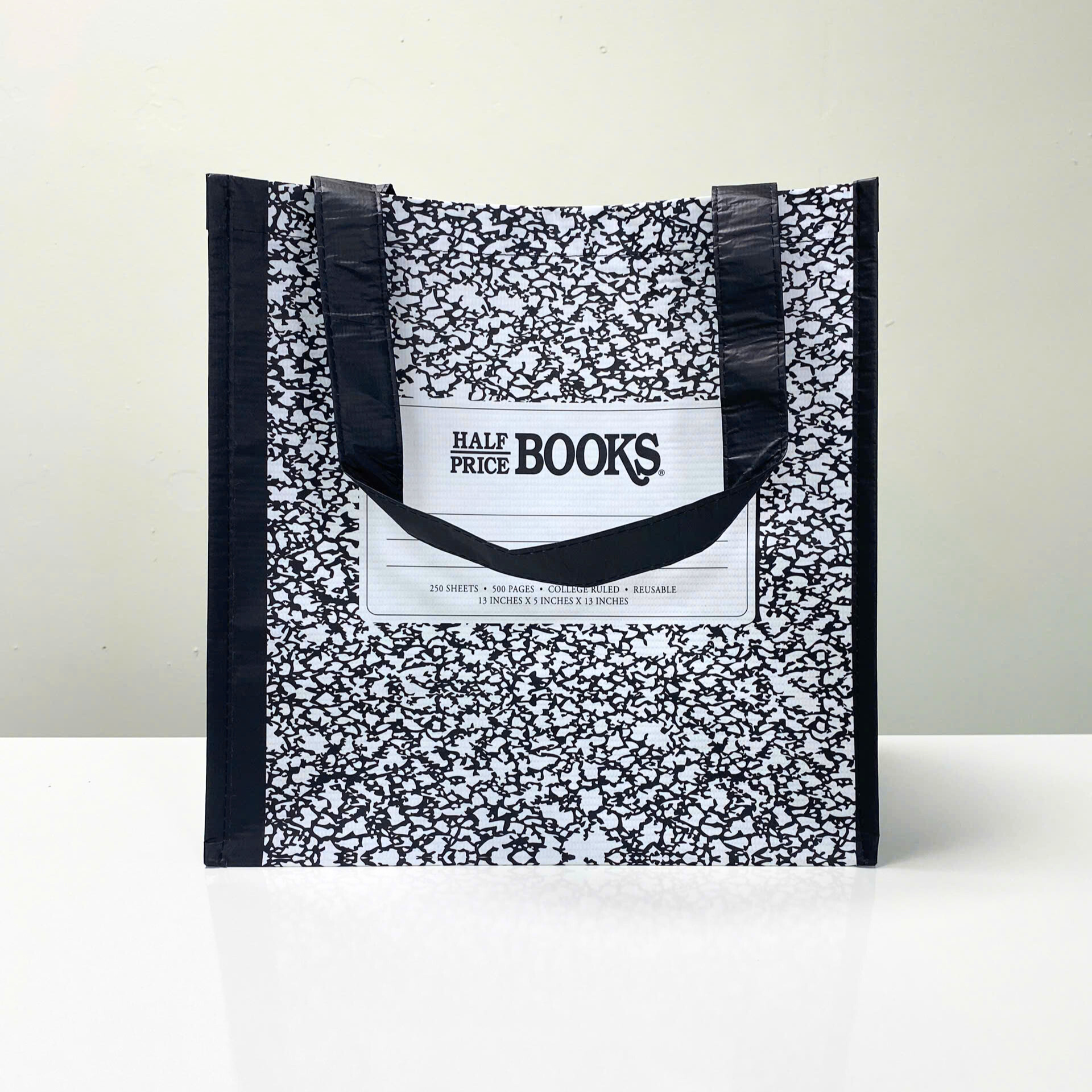

Recycled PP is the go-to material for woven shopping bags and reusable carry bags used in supermarkets, fashion stores, and events. They are durable, reusable many times, and a sustainable alternative to single-use plastic bags.

Recycled PET (rPET) is widely used for beverage bottles, transparent food packaging, and zipper pouches, helping keep food safe and supporting a circular economy.

4.2. Industrial uses

PP recycled resin is perfect for sacks and bulk bags that carry rice, sugar, fertilizer, and animal feed. Its high strength and excellent print quality make it ideal for heavy-duty packaging and export markets.

rPET is also spun into polyester fibers used for textiles, backpacks, carpets, and car seat fabrics, giving plastic waste a second life and reducing the need for virgin materials.

4.3. Agriculture

Recycled PP bags are commonly used for seed packaging and fertilizer bags, protecting contents from moisture and sunlight, reducing spoilage, and maintaining quality during storage and transport.

4.4. Other plastics (HDPE & LDPE)

While HDPE and LDPE can also be recycled into trash bags or film wraps, they are less preferred due to lower recycling rates and higher contamination issues. They are still used in some applications but face challenges in collection and processing.

5. Key tips for buying recycled plastic bags in bulk

5.1. Choose the right type for your needs

Recycled PP is strong and load-bearing – perfect for rice bags, fertilizer sacks, animal feed, and other heavy-duty industrial packaging.

Recycled PET (rPET) is clear and food-safe – ideal for beverage bottles, food packaging, and export products.

Choosing the right material from the start prevents costly returns and ensures your bags perform as expected.

5.2. Check quality before placing large orders

Always request samples to test thickness, load capacity, tear strength, and print quality. Skipping this step could result in bags that rip easily, poor printing, or a whole batch of defective products – delaying your production and deliveries.

5.3. Look for certifications and standards

Certifications like GRS or RCS confirm transparent sourcing and accurate recycled content. If using bags for food packaging, make sure the supplier provides food-contact safety certificates to avoid compliance issues or shipment rejections.

5.4. Work with reliable suppliers

Choose manufacturers with proven experience and references from international markets. Make sure your contract clearly defines quality standards, quantities, and lead times to avoid late deliveries, shortages, or inconsistent product quality.

5.5. Negotiate pricing and after-sales support

Compare costs with virgin plastic bags and balance price with sustainability benefits. Select suppliers who offer design support, provide documentation for customs, and have clear return/replacement policies – this saves time and prevents headaches during export.

6. Why choose K-Packing for recycled plastic bags?

K-Packing is a trusted Vietnam-based manufacturer, specializing in high-quality recycled plastic bags — the perfect solution for retail, industrial packaging, and export markets.

- Durable & Reliable: Made from recycled PP and rPET with excellent strength and tear resistance, ideal for heavy-duty use and multiple reuses.

- Eco-Friendly Choice: Produced from certified recycled materials, helping your business reduce carbon footprint and meet global sustainability goals.

- Fully Customizable: Select size, material type (rPET, rPP), thickness, color, printing, and handle style to match your product and brand requirements.

- Certified Quality: Manufactured in ISO 9001:2015 & ISO 14001:2015 certified facilities and compliant with GRS/RCS standards, ensuring transparency and export readiness.

- Cost-Effective & Efficient: Factory-direct pricing reduces costs by 10–15% on bulk orders, plus 50% off DHL shipping thanks to our major-agent status.

- Dedicated B2B Support: From sampling and testing to full production and documentation, we provide end-to-end assistance for hassle-free sourcing.

Request a Quote Today

📧 Email: info@k-packings.com

📞 Hotline: (+84) 855 555 751

Addresses:

USA: 7319n. Loop 1604 E, San Antonio TX 78233, United States.

ANGOLA: Av. Pedro de Castro Van-Dúnem Loy, Luanda, Angola.

VIETNAM: 169 Nguyen Ngoc Vu Street, Cau Giay District, Hanoi.