Choosing the right shopping carry bags manufacturer can significantly reduce your procurement expenses. By partnering directly with a factory that controls materials, production, and quality in-house, your company can save up to 30% while maintaining consistent performance across every shipment. This advantage helps you strengthen margins, stabilize supply, and secure long-term cost efficiency.

To support your decision-making process, the following information will help you easily identify the right products and the most suitable supplier for your needs. Let’s get started.

1.Technical Specifications for Shopping Carry Bags

Here are the standard technical specifications for shopping carry bags, designed to help you quickly determine which materials and performance levels match your requirements. If you need customized specifications or additional testing, feel free to send us your request:

- Material Thickness: Non-woven PP bags should be 70–100 GSM, and paper bags 120–250 GSM. Each production lot must include a GSM/Micron test photo, helping you easily verify thickness using your own GSM tester or reference samples.

- Load Capacity: Bags need to pass a 5–10 kg static test and a 100–200 m dynamic walking test. Handles and seams must not stretch or tear. A test video or report should be provided so you can repeat the same test with weights at your warehouse.

- Printing Method: Factories must confirm the printing method – Flexo, Rotogravure, Offset, or Silk Screen – and state whether plate/cylinder charges are included. You can verify the method through visible signs like dot patterns (Flexo), smooth gradients (Gravure), or crisp lines (Offset).

- Handle & Reinforcement: Paper bags require a bottom card and turn-top reinforcement, while non-woven/plastic bags need reinforced seams or heat sealing. For bags carrying 3–5 kg+, reinforcement is mandatory. Request close-up photos so you can visually check construction strength.

- Quality Control Reports: Factories should provide GSM/Micron, Tensile Strength, and Bursting Strength tests. You can confirm consistency by doing simple spot checks—pulling handles, pressing panels, or comparing numbers with past orders. Third-party inspection is optional but helpful.

- Defect Rate: The acceptable defect rate should be below 1–2%. When receiving goods, you can verify this quickly by checking a small sample of cartons for misprints, weak handles, stains, or incorrect sizes.

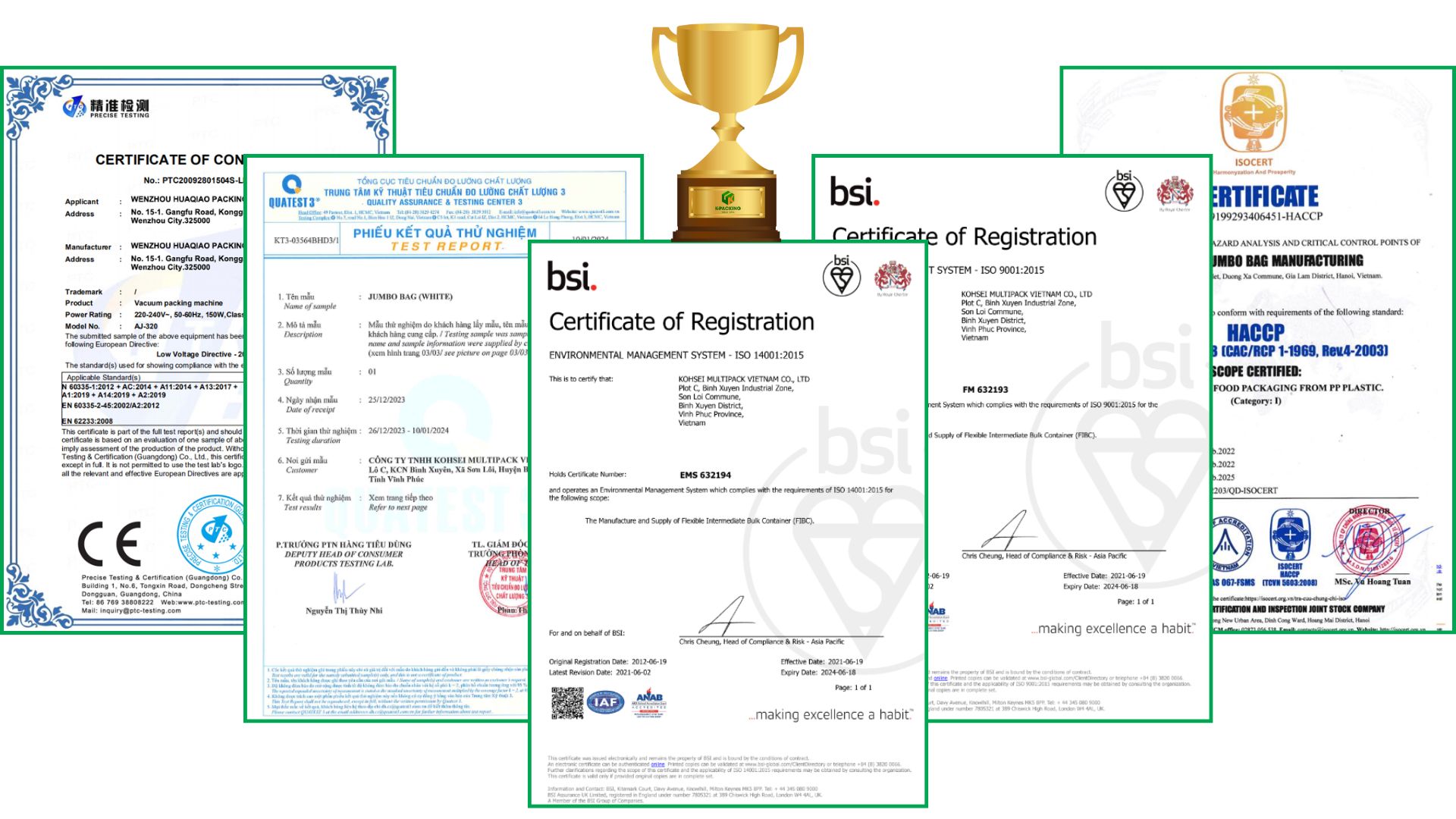

- Certifications: Suppliers must provide valid FSC, GRS, and BSCI/SMETA certificates (within 12 months). You can confirm authenticity by checking each certificate code on its official registry and ensuring the factory name matches.

2. Key Factors You Should Evaluate When Sourcing

This section outlines the essential factors you should review when sourcing shopping carry bags. These insights help you assess supplier capability, pricing transparency, and long-term reliability. If you have specific requirements or need customized support, our team is ready to assist you:

2.1. Cost Breakdown – Foundation for Evaluating Price Integrity

In the production of shopping carry bags, raw materials represent approximately 60–70% of the total cost and fluctuate with global oil prices, pulp prices, and currency movements. Comparing these market indicators with the quotation allows you to assess whether the pricing reflects real material conditions. Labor and processing typically account for 15–20% and shape the consistency of finishing quality, including handle construction, seam strength, and print accuracy. Operational expenses and profit margins make up the remaining 10–20% and generally remain stable across manufacturers.

When material prices decrease but the factory’s quotation remains unchanged, this cost structure gives you a factual basis to request a revised offer or a transparent explanation. This ensures that your sourcing decisions are based on market-aligned and traceable pricing.

K-Packings provides weekly material-based pricing updates to help you maintain cost control and avoid artificially inflated quotations. Understand the real cost structure of shopping carry bags and gain the pricing transparency you need to reduce expenses and negotiate with confidence.

2.2. MOQ & Lead Time – Indicators of True Manufacturing Capacity

MOQ requirements for shopping carry bags depend on production technology. Offset-printed paper carry bags typically require 1,000–3,000 units per design because of costly printing plates and die-cut tools. Plastic and non-woven carry bags produced on automated lines generally require 10,000–50,000 units depending on size, number of print colors, and handle reinforcement. A lower MOQ often indicates increased manual work or higher unit pricing.

Lead time is usually divided into two phases. The first phase takes 3–7 days for plate or cylinder preparation and artwork approval. The second phase involves 10–20 days of mass production, followed by domestic transport or international shipping under FOB/CIF terms. Requesting the factory’s daily production capacity enables you to evaluate whether timelines are realistic and whether the supplier can maintain consistency. Checking how the factory responds to a 30–50% production increase also helps you assess scalability during peak demand.

K-Packings operates multiple high-capacity production lines, ensuring stable lead times and flexible scale-ups when your shopping carry bag orders rise unexpectedly.

2.3. Certifications – Essential for Retail Chains and Export Markets

Certifications are essential for buyers supplying large retail chains or exporting shopping carry bags to regulated markets. FSC certification ensures that paper used in carry bags originates from responsibly managed forests or recycled sources; requesting certificates valid within the past 12 months ensures compliance. For carry bags incorporating recycled plastic or non-woven materials, GRS verifies the recycled content percentage (typically 20–50%) and ensures full supply-chain traceability, including environmental and labor-related criteria.

Social compliance certifications such as SMETA or BSCI are required by most international retailers and review labor practices, workplace safety, and ethical standards. Requesting recent audits or certificate copies helps confirm a factory’s readiness to meet global compliance expectations.

K-Packings maintains active FSC, GRS, and BSCI/SMETA certifications, enabling your shopping carry bags to meet retailer specifications and international compliance standards with reduced risk.

2.4. Quality Verification – Factory Audit and Sample Evaluation

Quality verification for shopping carry bags involves evaluating both the production environment and the pre-production samples. A competent factory manages material thickness using GSM or Micron testers, controls printing quality in clean zones, and applies structured QC protocols across each stage of manufacturing. Observing these practices during a factory audit helps determine whether the supplier can maintain consistency through large-scale production.

Sample evaluation ensures alignment between technical specifications and actual product performance. Measuring GSM or Micron thickness, checking handle and seam strength, verifying ink adhesion, and assessing overall finishing quality are essential steps before approving bulk production. Any inconsistency at this stage often indicates potential risks in long-run manufacturing, so early verification is critically important.

K-Packings applies a dual-layer QC system supported by professional testing equipment, in-house inspectors, and golden sample benchmarking. We provide free samples for your evaluation and welcome factory visits so you can verify our production capabilities directly.

Conclusion

Vietnam has emerged as one of the most competitive destinations for sourcing shopping carry bags, supported by factory-direct pricing, stable material quality, and efficient global logistics. Many international buyers secure 10–20% cost reductions compared with other Asian markets. Within this landscape, K-Packings Vietnam is recognized for consistent quality, reliable production capacity, and proven export experience to more than 30 countries.

Request a Free Shopping Carry Bag Sample for Your Company

To help you verify manufacturing capability before selecting a long-term partner, you may request a Free Shopping Carry Bag Sample from K-Packings Vietnam.

The sample allows you to directly assess material thickness, handle strength, seam durability, print precision, and overall finishing quality according to international standards.

K-Packings provides fast quotations, full OEM/ODM customization, and complimentary sample delivery to your location, ensuring you can evaluate product performance with clarity and confidence.

WhatsApp / Phone: (+84) 855 555 751

Email: [info@k-packings.com](mailto:info@k-packings.com) | [sale@k-packings.com](mailto:sale@k-packings.com)

Addresses:

Nguyen Ngoc Vu Street, Cau Giay District, Hanoi

ANGOLA: Av. Pedro de Castro Van-Dúnem Loy, Luanda

USA: 7319 N. Loop 1604 E, San Antonio, TX 78233

Reviews

There are no reviews yet.